Bitte blockieren Sie keine Werbung auf unserer Website. Klicks auf Anzeigen helfen uns, zu existieren, zu wachsen und für Sie nützlicher zu werden!

Technische Spezifikationen von Umwälzpumpen

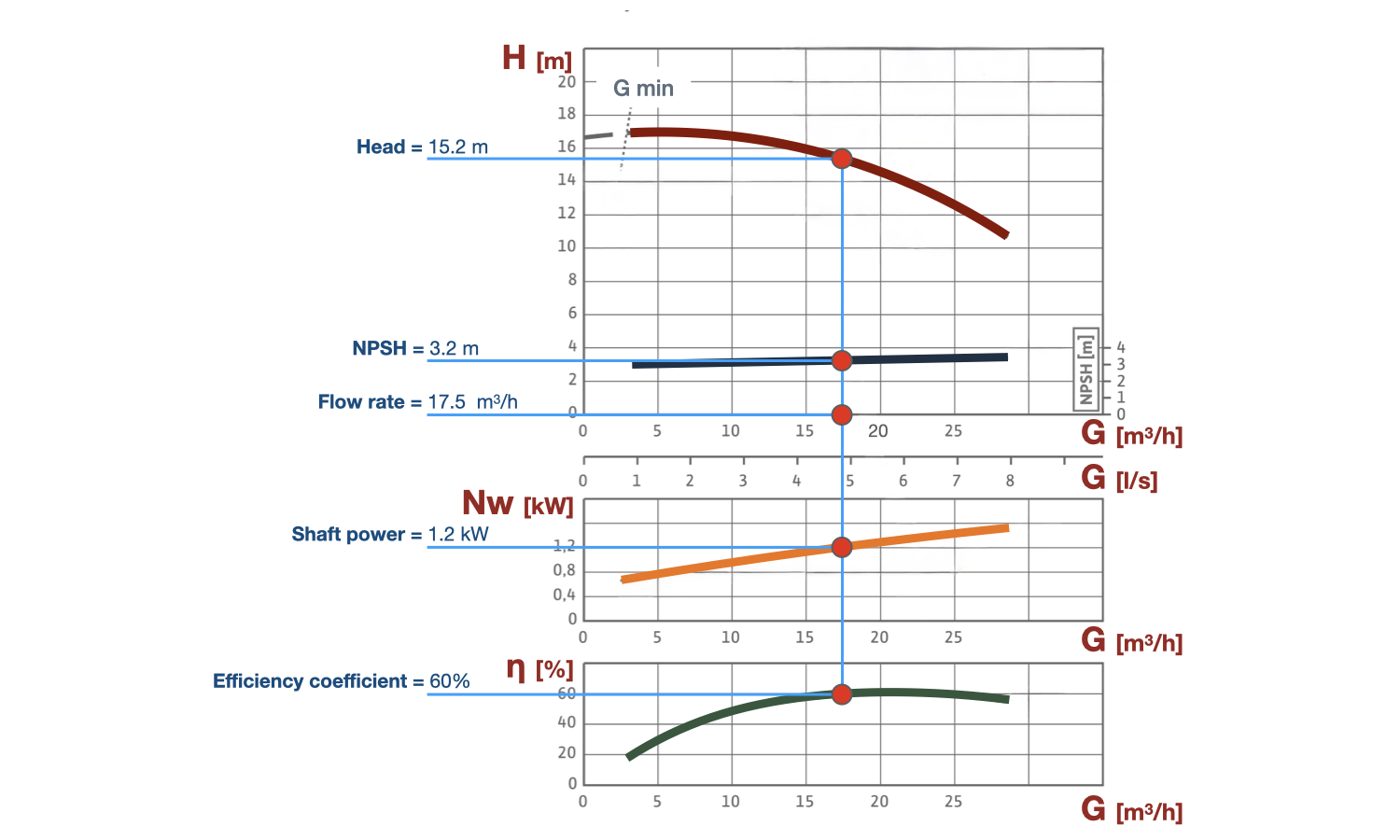

Förderhöhe - H [m] - der Druckunterschied zwischen den Ein- und Auslassstutzen der Pumpe. Die Förderhöhe der Umwälzpumpe entspricht immer der Summe der Druckverluste aller Elemente des Umwälzkreises. Die Förderhöhe der Pumpe wird nicht von der Höhe des angeschlossenen Systems beeinflusst, sie muss lediglich die hydraulischen Verluste im Umwälzkreis abdecken.

Förderstrom - G [m³/h] - das ist das Volumen an Wasser, das die Pumpe pro Zeiteinheit fördert. Der tatsächliche Förderstrom der Umwälzpumpe wird durch Überlagerung der Druck-Förderstrom-Kennlinie der Pumpe mit der hydraulischen Kennlinie des Umwälzkreises bestimmt.

Druck-Förderstrom-Kennlinie der Pumpe - dies ist die grafische Darstellung der Beziehung zwischen dem Förderstrom der Pumpe und der Förderhöhe in den Koordinaten [m³/h]/[m]. Der Hersteller erstellt die Druck-Förderstrom-Kennlinie für jeden Pumpentyp basierend auf Daten, die aus Prüfungen von Mustern gewonnen wurden, und gibt diese in technischen Katalogen an.

Hydraulische Kennlinie des Umwälzkreises - dies ist die grafische Darstellung der Beziehung zwischen den Druckverlusten im Umwälzkreis und der Wassermenge, die durch ihn fließt, in den Koordinaten [m³/h]/[m]. Da sich die Druckverluste im Umwälzkreis proportional zum Quadrat der Änderung der Wassermenge ändern, wird die hydraulische Kennlinie immer als Parabel dargestellt.

Um beispielsweise den Förderstrom im Heizsystem zu verdoppeln, muss die Förderhöhe der Pumpe um 2² = 4 Mal erhöht werden.

Arbeitspunkt der Umwälzpumpe - dies ist der Punkt, an dem sich die Druck-Förderstrom-Kennlinie der Pumpe und die hydraulische Kennlinie des Umwälzkreises schneiden. Der Arbeitspunkt zeigt den tatsächlichen Förderstrom und die Förderhöhe der Pumpe im Umwälzkreis an.

NPSH (Net Positive Suction Head) — [m] — dies ist der minimale absolute Druck am Saugstutzen der Pumpe, bei dem der Betrieb ohne Kavitationsbildung garantiert wird. Der NPSH-Wert wird individuell für jedes Pumpenmodell basierend auf Prüfungen bestimmt und in den Katalogen in Form von Diagrammen angegeben. Je höher die Temperatur des geförderten Wassers, desto höher ist der NPSH-Wert.

Nutzleistung — Nu [W] — entspricht der Energie, die pro Zeiteinheit an das Fördermedium übertragen wird.

Nu = ρ · g · Q · H

Wellenleistung — Nw [W] — dies ist die mechanische Leistung, die auf die Pumpenwelle übertragen wird. Die mechanische Leistung ist höher als die Nutzleistung aufgrund hydraulischer Verluste und Reibungsverluste im Laufrad.

Nw = Nu / η

Wirkungsgrad — η [%] — ist ein Effizienzmaß für die Umwälzpumpe und wird als Verhältnis der Nutzleistung zur Wellenleistung definiert.

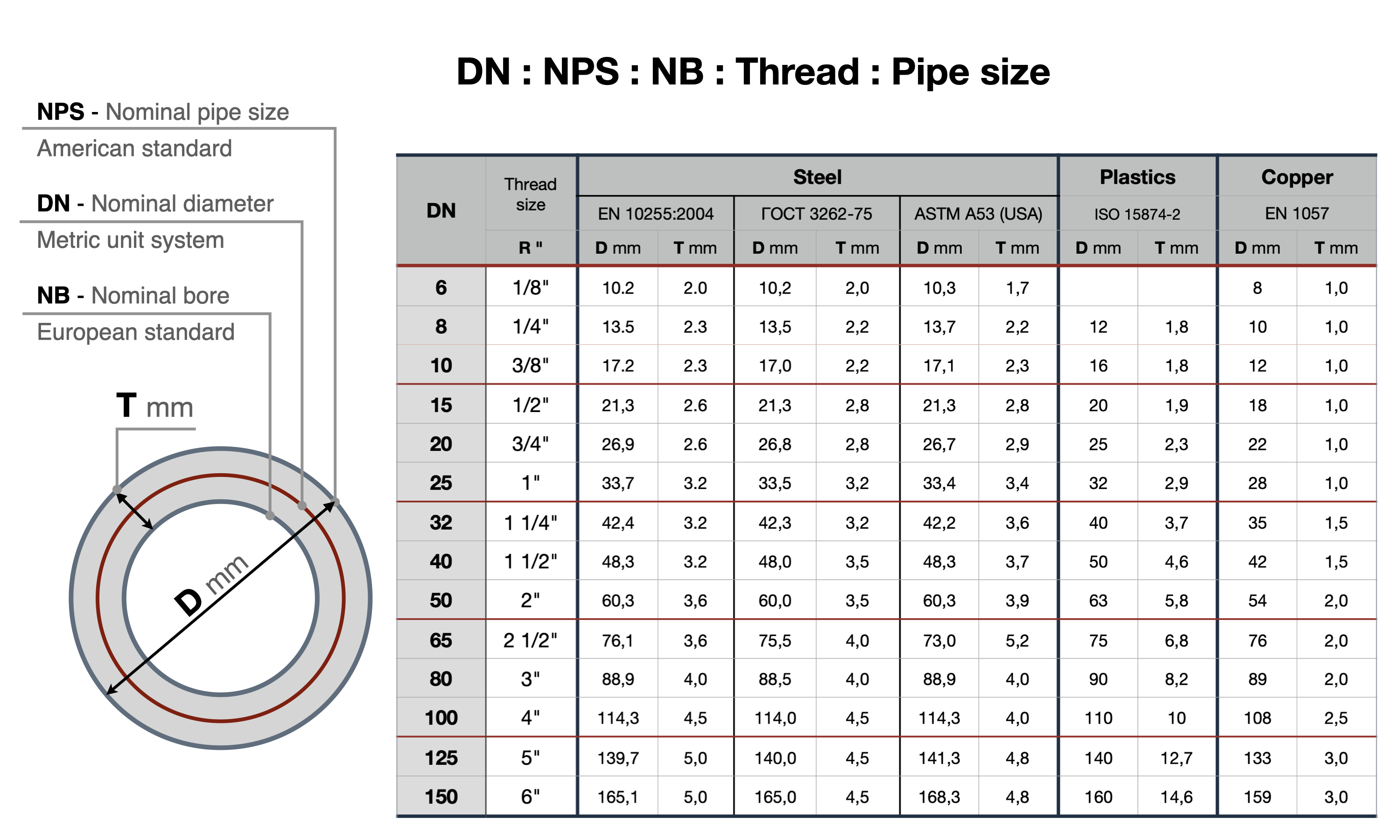

Nennweite — DN — ist eine dimensionslose Bezeichnung der Baugröße, die dem Innendurchmesser der Pumpenanschlüsse in Millimetern ungefähr entspricht. Die Nennweiten werden zur Vereinheitlichung der Rohrleitungsarmaturen verwendet.

Nenndruck — PN [bar] — dies ist der maximale Überdruck des Arbeitsmediums bei einer Temperatur von 20°C, bei dem ein sicherer und langfristiger Betrieb gewährleistet ist.

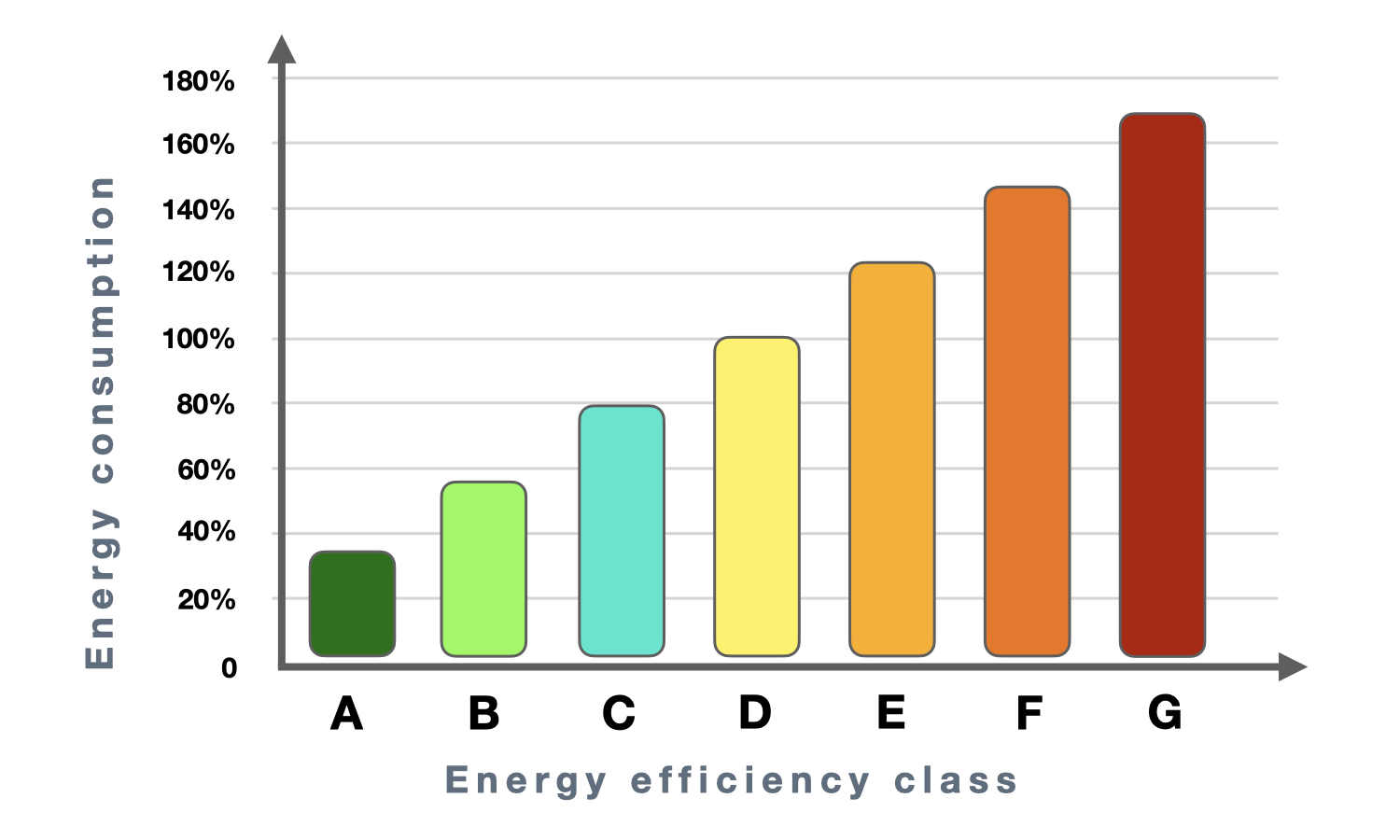

Energieeffizienzklasse — [A-G] — ist eine allgemein anerkannte Klassifizierung für Haushaltsprodukte, die die Effizienz des Energieverbrauchs widerspiegelt. Die Energieeffizienzklassen werden mit lateinischen Buchstaben von A bis G gekennzeichnet. Produkte mit der Kennzeichnung A verbrauchen am wenigsten Energie, während Produkte mit der Kennzeichnung G am meisten Energie verbrauchen.

Vergleicht man Umwälzpumpen mit ähnlichen hydraulischen Eigenschaften, aber unterschiedlichen Energieeffizienzklassen, stellt man fest, dass der Unterschied im Energieverbrauch zwischen zwei benachbarten Klassen 22% beträgt. Eine Pumpe der Klasse A verbraucht nur etwa 33% der Energie, die eine Pumpe der Klasse D benötigt.

Frage : Kommentar : Rückmeldung

809

Katalog von

Katalog von Umwälzpumpen

DAB

DAB

DAB

DAB

Wilo

Wilo

Wilo

Wilo

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

Calpeda

Calpeda

Calpeda

Calpeda

Calpeda

Grundfos

Wilo

Wilo

Wilo

Wilo

Wilo

Calpeda

Calpeda

Grundfos

Grundfos

Grundfos

Grundfos

Grundfos

DAB

DAB

Smedegaard

Smedegaard

Smedegaard

Lowara

Lowara

Lowara

Lowara

Lowara

IMP Pumps

Tutorial Grundfos

Tutorial Grundfos