Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

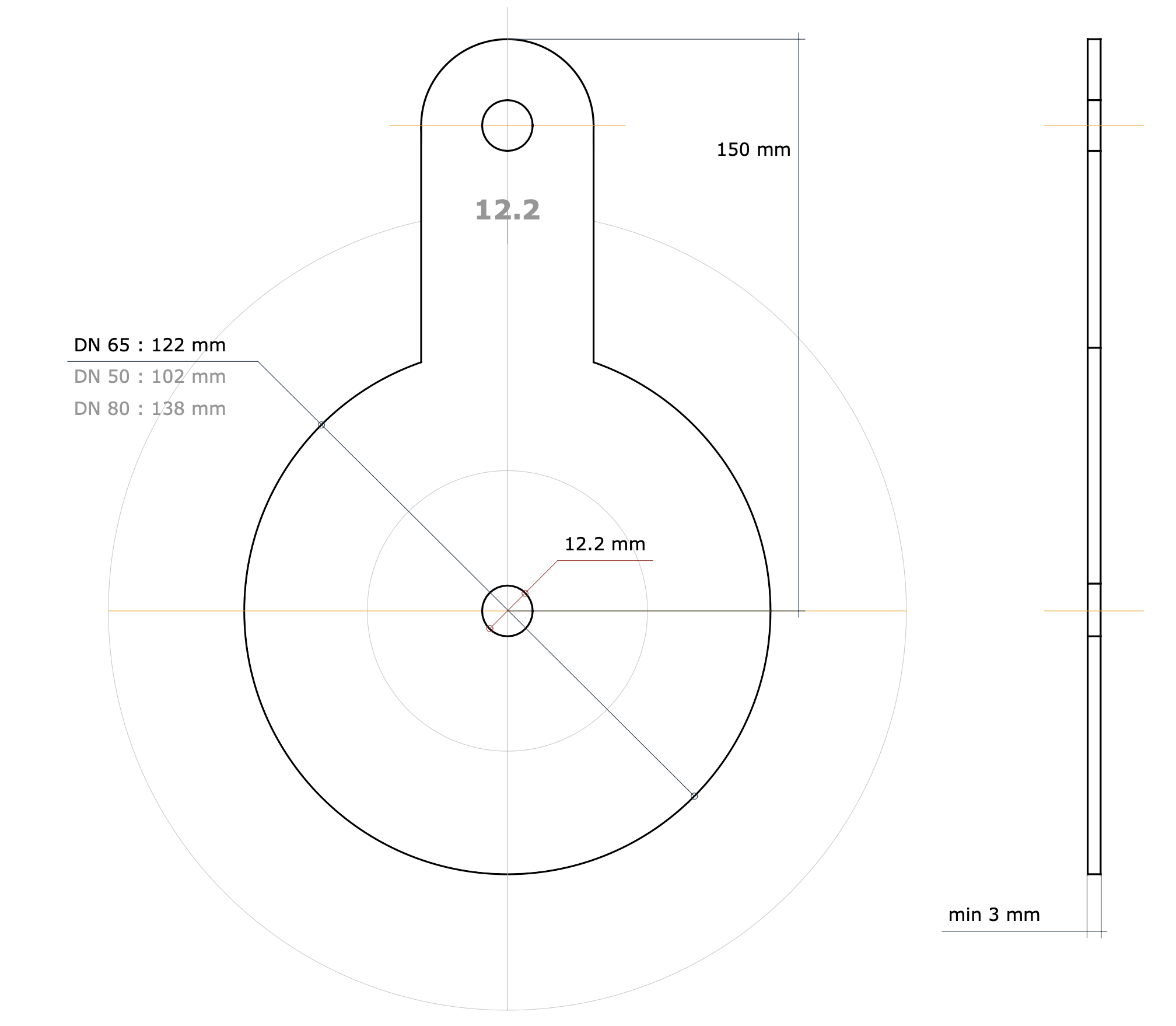

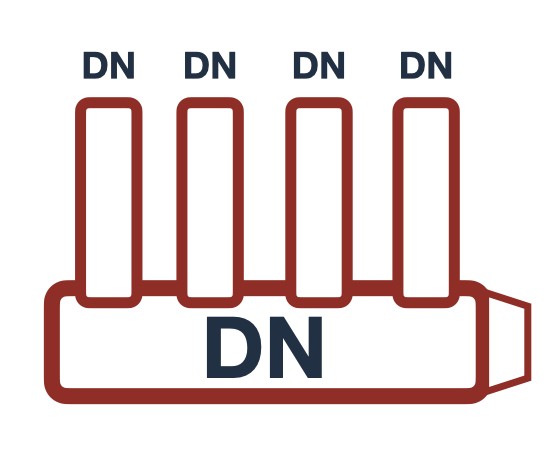

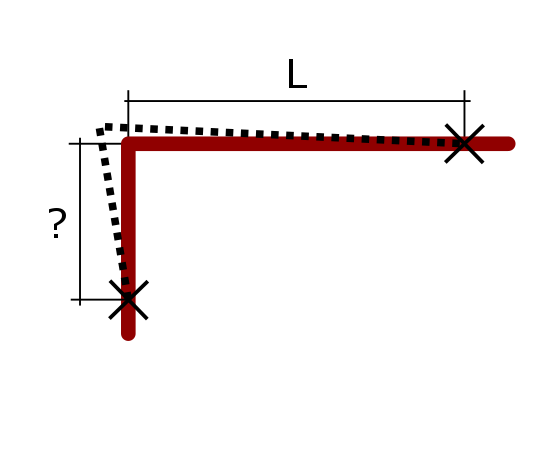

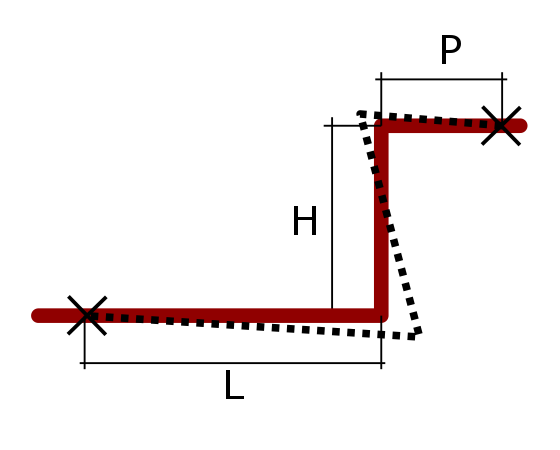

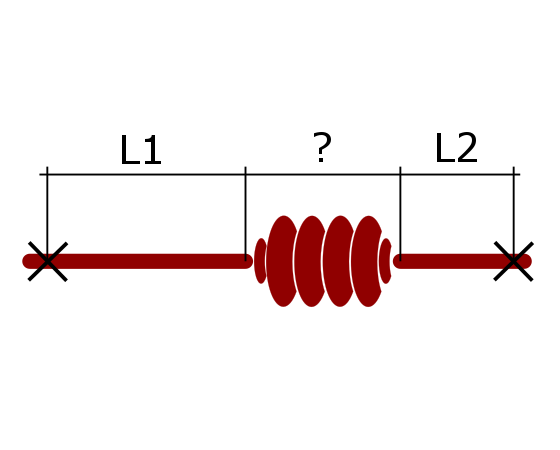

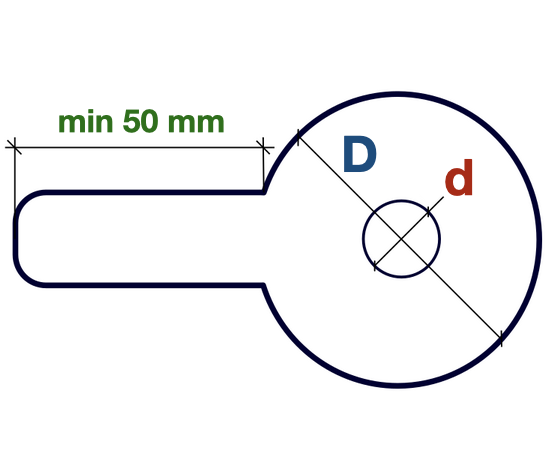

Calculation of the orifice plate is performed to determine the diameter of the diaphragm opening, which will provide the specified pressure reduction at the calculated water flow rate.

Throttle diaphragms are designed to regulate excess pressure in systems with a constant hydraulic regime and have been widely used in heat networks for hydraulic balancing. However, with the emergence of mandatory requirements for heating stations to be equipped with automatic regulators, the relevance of throttle diaphragms has decreased.

This is due to the fact that the pressure loss across the diaphragm changes according to the quadratic law with a change in water flow, which means that a two-fold increase in flow results in a four-fold increase in pressure loss across the diaphragm, while a three-fold decrease in flow will result in a nine-fold decrease in the pressure loss across the diaphragm (3² = 9 times).

In modern heat supply systems with variable flow, automatic differential pressure controllers are used, which are able to ensure a stable hydraulic regime regardless of pressure fluctuations in thermal networks and the operation of the control valve, as well as to prevent excess flow of the coolant.

A functional analogue for systems with a constant hydraulic regime is balancing valve, the resistance of which can be changed by manual adjustment, and the specified setting to fix.

Despite this, throttle diaphragms are still used to reduce capital costs or due to the conservative requirements of traditionalists in heat supply organizations.

Calculation of the throttle washer orifice diameter

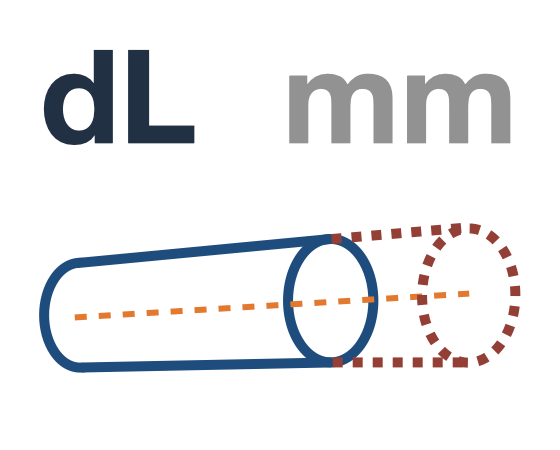

D = 10 *(G²/dP)0.25, mm

- G – water flow, m³/h;

- dP – pressure loss, mH2O

Online Calculations

Online Calculations

EXAMPLE

EXAMPLE