Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Calculation of the U-shaped pipe compensator

Calculation of the compensating capacity of a given-size compensator

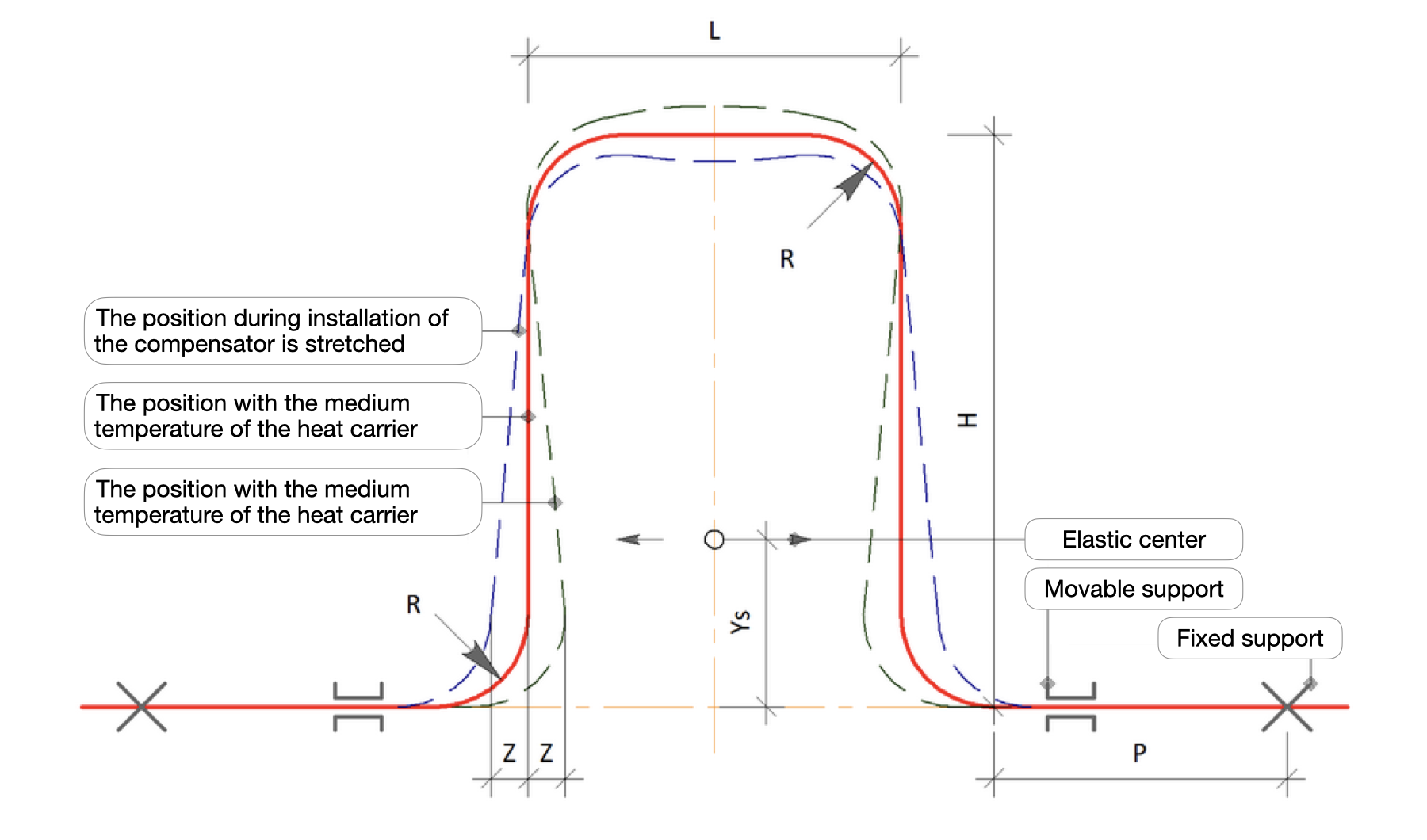

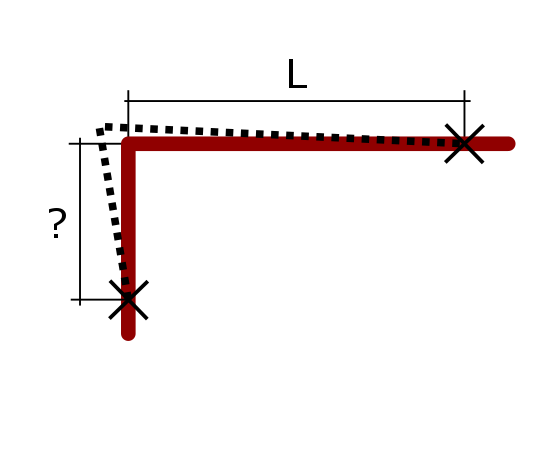

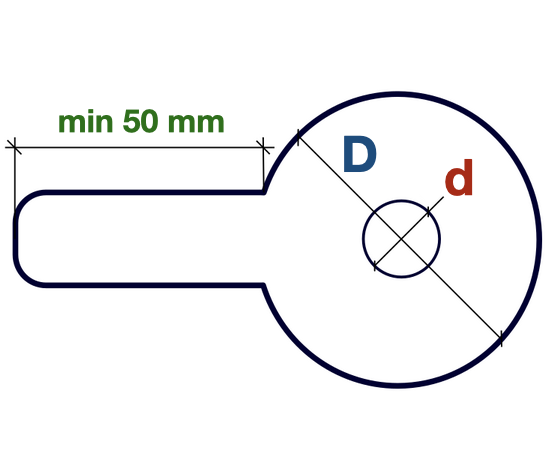

Calculation of the U-shaped pipe compensator consists in determining the minimum dimensions of the compensator, which are sufficient to compensate for temperature deformations of the pipeline. By filling out the above form, you will be able to calculate the compensating capacity of the U-shaped compensator by its dimensions.

Recommendations for calculation

- The maximum tension in the back of the compensator is recommended to be in the range from 80 to 110 MPa.

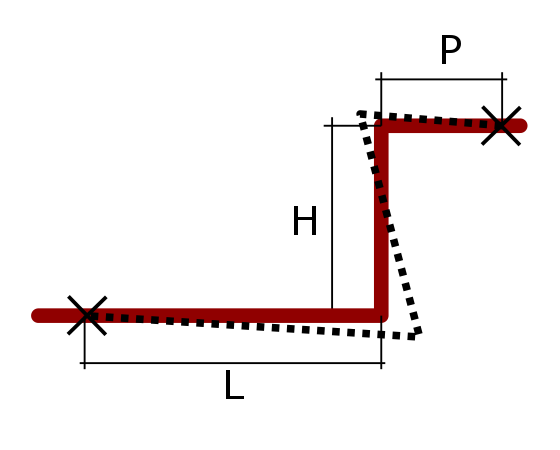

- The optimal ratio of the overall length compensator to diameter of the pipe is recommended to be in the range H/DN = (from 10 ... to 40), while the Overall length of the compensator in 10DN corresponds to the DN350 pipeline, and the Overall length in 40DN to the DN15 pipeline.

- The optimal ratio of the width of the compensator to its margin is recommended to be in the range of L/H= (from 1 ... to 1.5), although other values may be accepted.

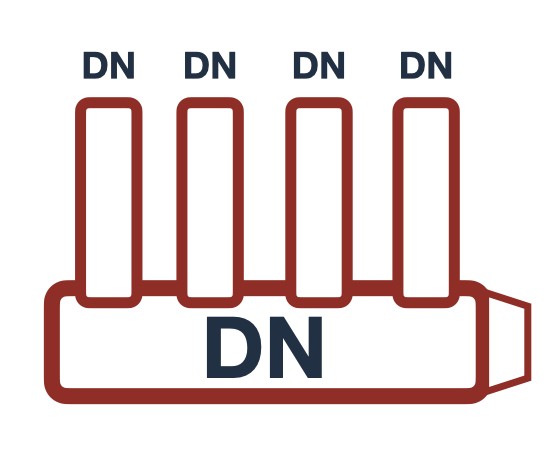

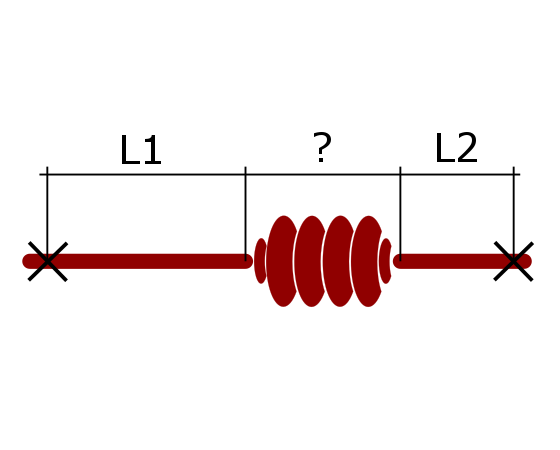

- If it is necessary to install a compensator of too large sizes to compensate for the thermal elongation of the pipeline, it can be replaced with two smaller compensators.

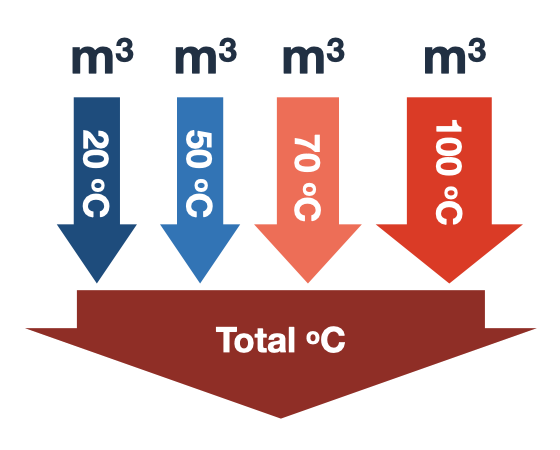

- When calculating the thermal elongation of the pipeline, the temperature of the coolant should be taken as the maximum, and the temperature of the environment surrounding the pipeline as the minimum.

The following restrictions are accepted in the calculation

- The pipeline is filled with water or steam

- Pipeline made of steel pipe

- The maximum temperature of hot water or steam does not exceed 200 °С

- The maximum pressure in the pipeline does not exceed 1,6 МPa (16 bar)

- The compensator is installed horizontally

- The compensator is symmetrical, and its arms are of the same length

- Fixed supports are considered absolutely rigid

- The pipeline does not feel wind pressure and other loads

- The resistance of the frictional forces of the movable supports during thermal elongation is not taken into account

- The elbow are smooth

Installation recommendations

- It is not recommended to place fixed supports at a distance of less than 10DN from the U-shaped compensator, because the transfer of the support clamping moment to it reduces flexibility.

- The sections of the pipeline from the fixed supports to the U-shaped compensator are recommended to be of the same length. If the compensator is not located in the middle of the section, but is shifted towards one of the fixed supports, then the forces of elastic deformation and tension increase by approximately 20-40%, in relation to the values obtained for the compensator located in the middle.

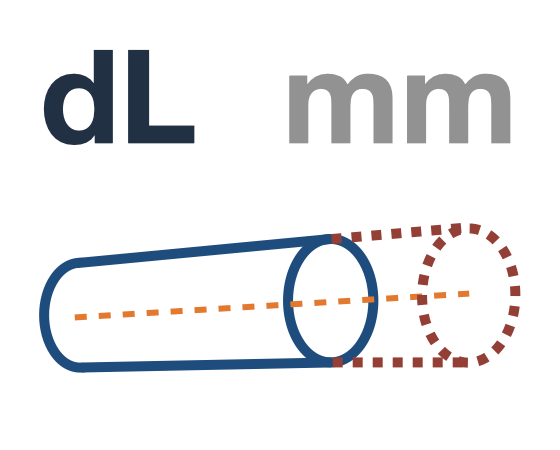

- To increase the compensating capacity, pre-stretching of the compensator is used. During installation, the compensator experiences a bending load, takes a non-stressed state when heated, and bends at the maximum temperature. Pre-stretching of the compensator by an amount equal to half the thermal elongation of the pipeline allows to increase its compensating capacity twice.

- For above-ground laying of all pipe diameters, regardless of the parameters of the hot-water.

- When laying in tunnels, channels and common collectors on pipelines from DN25 to DN200 at coolant pressure up to 16 bar.

- For ductless laying of pipes with diameters from DN25 to DN100.

- If the maximum temperature of the working environment exceeds 50°C

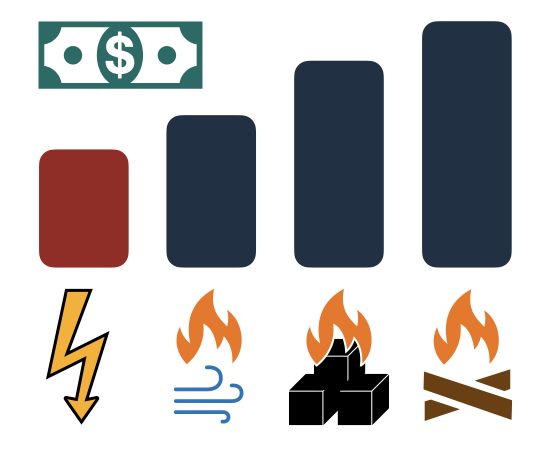

- High compensating ability

- Does not require maintenance

- Easy manufacturing

- Insignificant forces transmitted to fixed supports

- Many pipes are used for manufacturing

- Large occupied area

- High hydraulic resistance

Field of application

U-shaped compensators are used to compensate for temperature elongation of pipes on long straight sections, when there is no possibility of self-compensation of the pipeline due to turns of the heat network. The absence of compensators on rigidly fixed pipelines with a variable temperature of the working environment will lead to an increase in voltage capable of deforming and destroying the pipeline.

Flexible compensators are used

Advantages

Disadvantages

Online Calculations

Online Calculations

EXAMPLE

EXAMPLE