Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

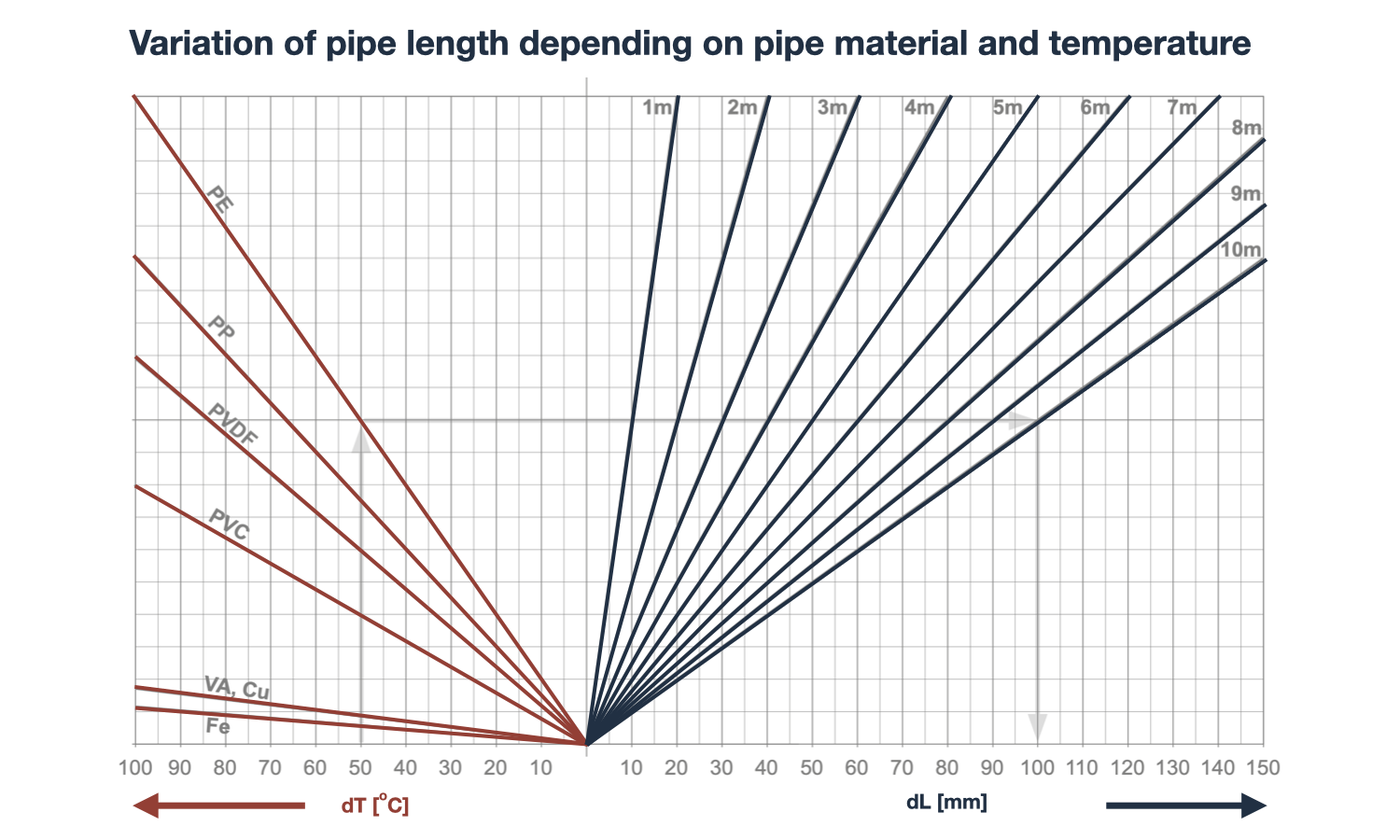

Calculation of variations in pipe length

depending on the material and temperature

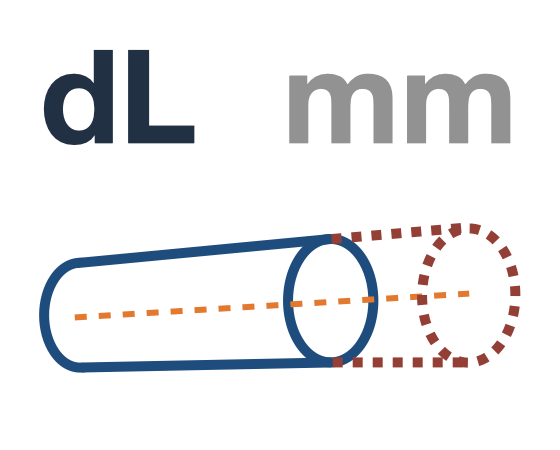

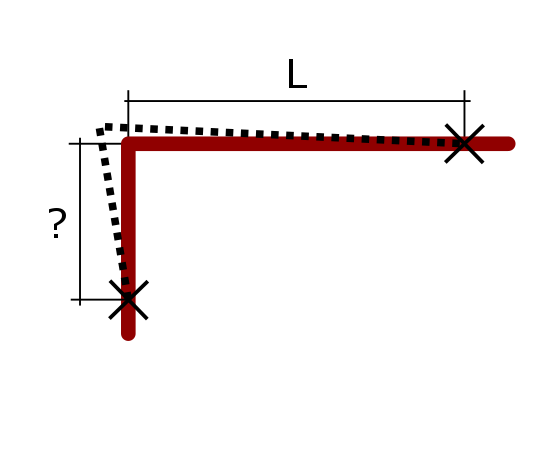

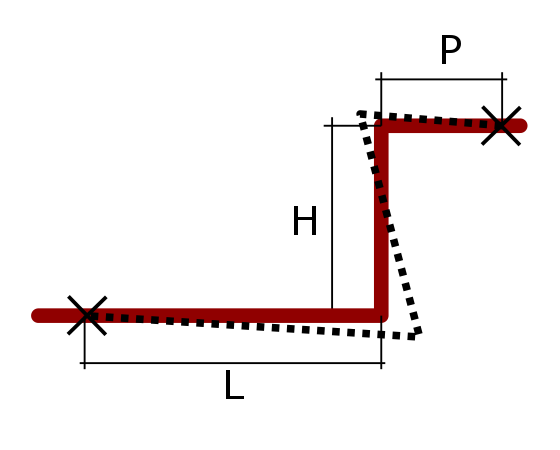

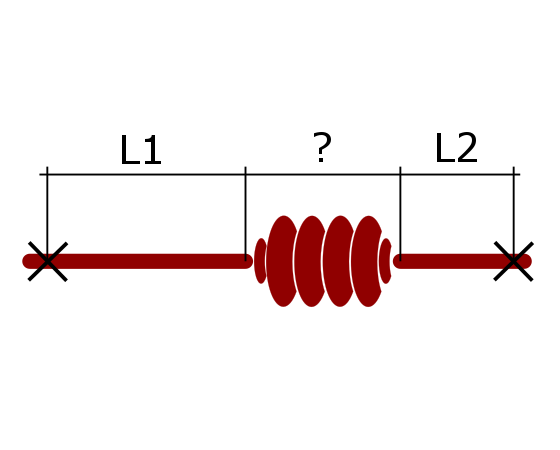

Calculation of thermal expansion of pipelines is performed to determine the increase in the length of the pipeline section during heating, the need to install compensators for temperature elongation, and to determine the required compensating capacity.

The variation in the length of a pipeline section due to temperature expansion can be determined using the following formula:

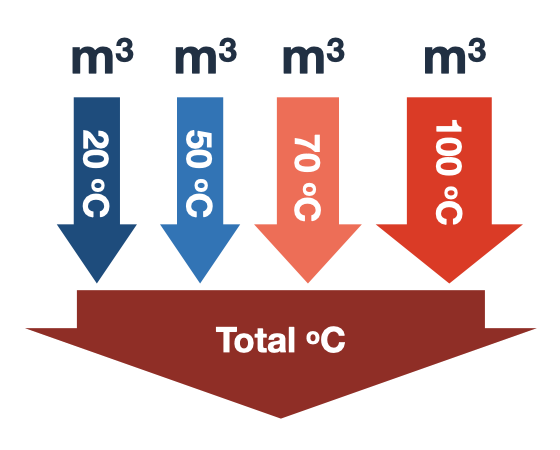

dL = a · L · (tmax – tmin), mm

tmax - the maximum temperature of the hot water in the pipeline, °C.

tmin - ambient temperature during pipeline installation, °C.

L - the length of the pipeline section, m.

a – The coefficient of linear thermal expansion, expressed in °C-1, depends on the physical properties of the material.

| pipe material | coefficient [ a ] |

|---|---|

| Steel | 0.013 |

| Copper | 0.017 |

| Polyethylene - PEX | 0.2 |

| Polybutylene - PB | 0.13 |

| Polypropylene - PP | 0.18 |

| Polyvinyl chloride - PVC | 0.08 |

Online Calculations

Online Calculations

EXAMPLE

EXAMPLE