Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Technical specifications of valves

Class of tightness - determines the maximum allowable leakage through the closed ball valve at atmospheric pressure on one side and water pressure of 1.1*PN on the other side. The water temperature during testing should be in the range of 5 to 40°C.

- Class A - no leakage

- Class B - no more than 0.0006*DN(mm) cm³/min

- Class C - no more than 0.0018*DN(mm) cm³/min

- Class D - no more than 0.006*DN(mm) cm³/min

Most ball valves have a class of tightness A.

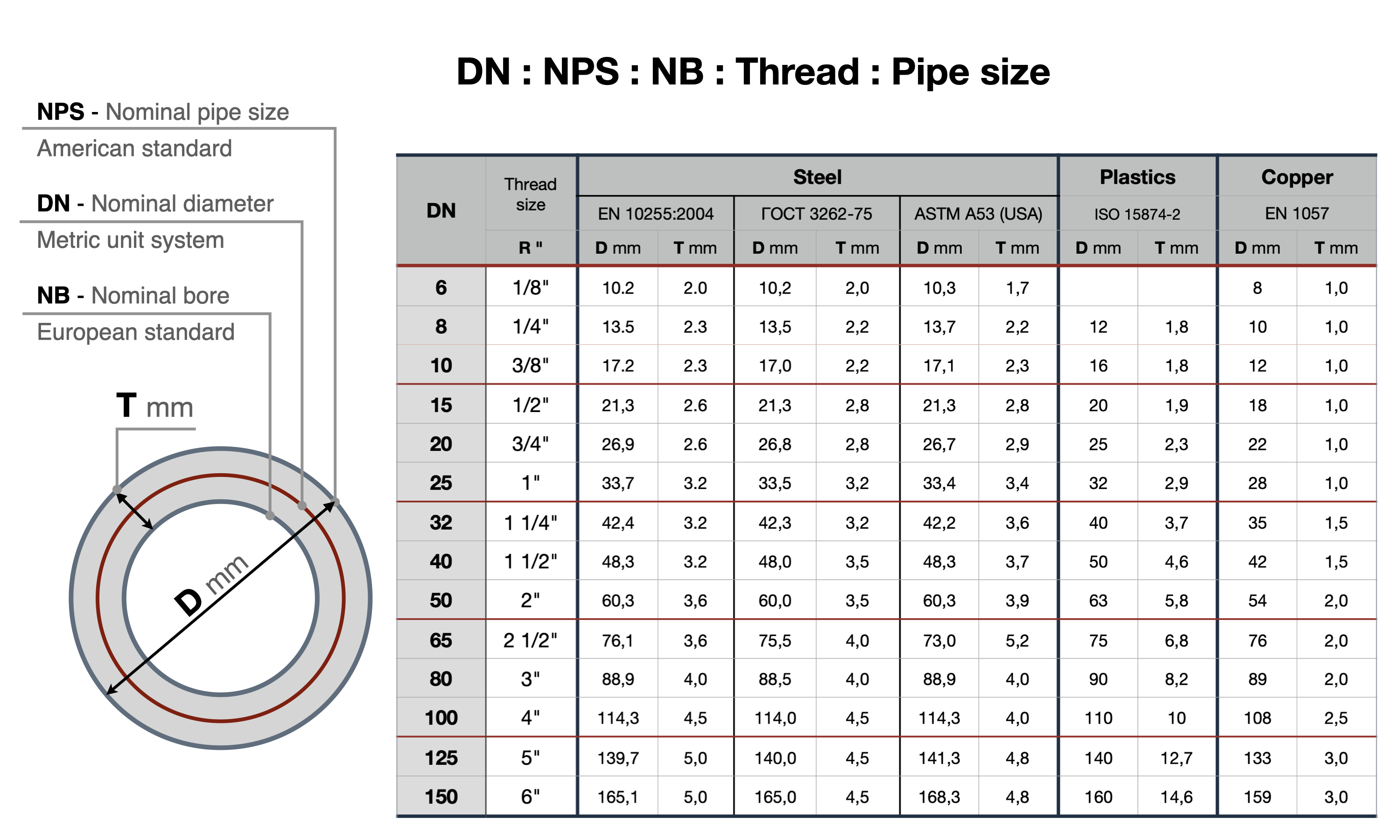

DN - nominal diameter - is used to indicate the sizes of pipeline fittings, has no dimension, and the numerical value of DN is approximately equal to the internal diameter of the connected pipeline in millimeters. Nominal diameter is applicable to all pipeline elements except pipes and components characterized by an external diameter.

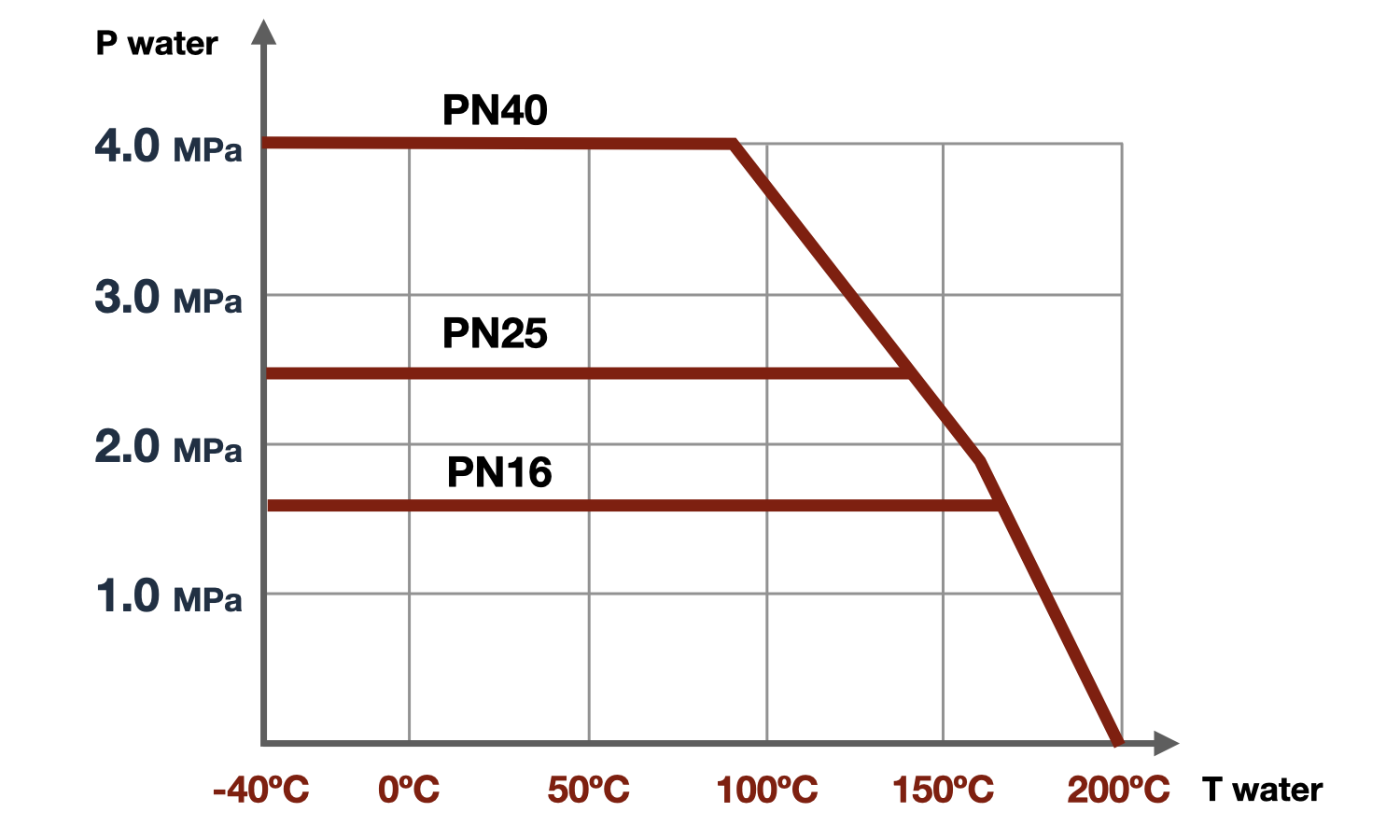

PN - nominal pressure - is the maximum excess pressure of the working medium at a temperature of 20°C, at which prolonged operation of the ball valve is permissible.

Testing pressure - is the excess pressure that must be used for hydraulic strength and tightness testing with water at temperatures from 5 to 70°C, if a different test temperature is not specified in the passport of the ball valve or normative documentation.

Working pressure - is the maximum excess pressure at which the specified operating mode of the shut-off valve is ensured, taking into account the temperature of the working medium. The value of the working pressure is usually less than the value of the nominal pressure, so the mode of operation simultaneously with the maximum operating temperature and nominal pressure is not allowed.

Kvs - flow coefficient - is numerically equal to the flow rate of water in m³/h at a temperature of 20°C, at which the pressure drop on the valve is 1 bar. The value of the flow coefficient is used in hydraulic calculations to determine the pressure drop on elements of pipeline systems.

question : comment : feedback

335

Catalog of

Catalog of of ball valves

IVR

IVR

IVR

Genebre

Genebre

Ayvaz

Danfoss

Breeze

Breeze

Breeze

Breeze

Brandoni

Brandoni

Vexve

Vexve

Vexve

Vexve

Vexve

Vexve

Ukspar

FAF

FAF

Broen

Broen

Bray

LD

LD

Polix

Polix

Polix

Danfoss

Brandoni

IVR

Naval

Naval

Polix

Polix

FAF

Маршал

Маршал

Маршал

Genebre

Krom Schroder

EN 1092-1

EN 1092-1