Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Flow rate and Head of a Pump

Flow rate — G [m³/hr] — the volume of water delivered by the pump in unit time. The flow rate of the pump is determined by the operating point on its characteristic curve and, apart from the design features, depends on the rotational speed of the impeller and the hydraulic characteristics of the system.

The optimal flow rate of the pump is achieved at the maximum value of the efficiency coefficient. The actual flow rate of the pump can be determined from the head-flow rate curve, knowing the head created.

Head — H [m] — the difference in pressure between the inlet and outlet of the pump.

H = Hz + (Pv - Pn)/(ρg) + dh + (Cv² - Cn²)/(2g)

where

- Hz - the geometric lift height, in meters, which is equal to the difference in liquid levels in the suction (upper) and delivery (lower) reservoirs;

- (Pv - Pn)/(ρg) - the height, in meters, corresponding to the pressure difference, in Pa, in the upper and lower reservoirs;

- dh - the sum of hydraulic losses (due to friction and local resistances) in the suction and delivery pipelines, in meters;

- (Cv² - Cn²)/(2g) - the height, in meters, corresponding to the difference in kinetic energy of the liquid at the flow rate Cv m/s at the outlet of the delivery pipeline into the upper reservoir and at the flow rate Cn m/s at the inlet of the suction pipeline from the lower reservoir;

- ρ - the density of the liquid

- g - the acceleration due to gravity, which is equal to 9.8 m/s²

If the pressure applied to the surface of the liquid in both reservoirs is the same, for example, in open reservoirs, and the liquid in both reservoirs is at rest, then the expression determining the pump head can be simplified:

H = Hz + dh

From the above expressions, it can be seen that the head of a pump lifting water is determined by the lifting height and head losses in the pipelines. In a closed circulation loop, (for example, a heating system), the pump head is determined by the sum of the head losses on all elements of the loop and does not depend on the height of the system and the location of the pump in it.

Pump head-flow curve — a graphical representation of the dependence of the pump head on its flow rate in coordinates Q [m³/h] / H [m]. The pump head-flow curve is the main characteristic used to select pumps and is presented in the catalogs of manufacturers in the form of graphs.

Operating point of the pump — the point at the intersection of the pump head-flow curve with a horizontal line drawn from the point on the ordinate axis corresponding to the developed head. To determine the actual flow rate of the pump from the operating point, a perpendicular is dropped to the flow rate axis (abscissa).

Thus, the pump flow rate is determined by the head it develops, which in booster pumps is determined by the lifting height and losses in the pipelines, and in circulation pumps — by the hydraulic characteristic of the circulation loop. Since, in the circulation loop, the change in head losses is proportional to the square of the change in flow rate passing through it, the hydraulic characteristic of the network in coordinates Q [m³/h] / H [m] is a parabola.

Suction head — Hs [m] — when water is taken from the lower reservoir, in which the surface of the water is subject to atmospheric pressure, the suction head of the pump corresponds to the difference in levels in meters between the axis of the impeller and the level of the liquid in the lower reservoir, minus the head loss in the pipeline connecting the lower reservoir and the pump.

The water is lifted from the lower reservoir due to the pressure difference, with a vacuum created in the impeller of the pump, and the water is subjected to atmospheric pressure. Since atmospheric pressure corresponds to a water column height of 10.3 meters, and the pump cannot create an absolute vacuum in the impeller — the suction head of the pump cannot exceed 8 meters.

Net Positive Suction Head (NPSH) — the minimum pressure in the suction pipe of the pump that ensures cavitation-free operation. The value of the NPSH is determined experimentally by pump manufacturers and is presented in the form of a graph depending on the pump flow rate.

Pump useful power — Nu [W] — corresponds to the energy transferred to the liquid per unit time.

Nu = ρ · g · Q · H

Power at the pump shaft — Nw [W] — mechanical power transmitted to the pump shaft. The mechanical power is greater than the useful power by the amount of hydraulic losses and losses due to friction in the impeller.

Nw = Nu / η

Pump efficiency — η [%] — the coefficient of performance that characterizes the degree of perfection of a centrifugal pump and is determined as the ratio of the useful power to the power at the shaft.

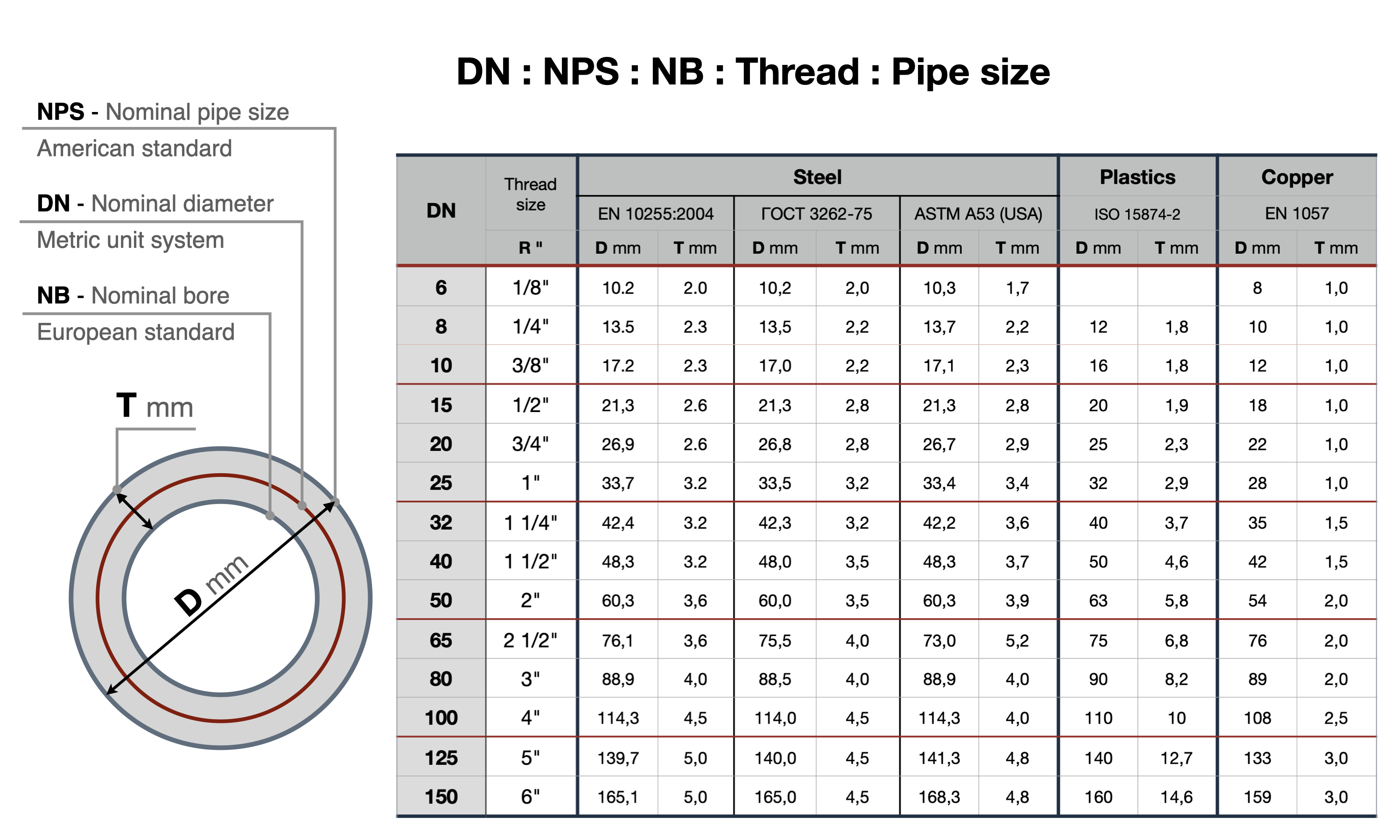

Nominal diameter — DN — numerical designation of the internal diameter of the connecting flanges of the pump, which is common for all pipeline elements. The nominal diameter of the pump is dimensionless, but its value is approximately equal to the internal diameter of the connected pipeline.

Nominal pressure — PN [bar] — the maximum excess pressure of water at a temperature of 20°C at which the pump can operate continuously.

question : comment : feedback

709

Tutorial Grundfos

Tutorial Grundfos Catalog of

Catalog of