Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Technical specifications of Centrifugal pump

Flow rate — G [m³/hour] — the volume of water that a pump delivers per unit of time. The optimal flow rate of a centrifugal pump is achieved at the maximum value of the efficiency coefficient. The actual flow rate depends on the head generated by the pump and can be calculated based on the specific pump's head-flow characteristic curve.

Head — H [m] — the difference in pressure between the inlet and outlet nozzles of the pump. In a closed circulation loop, the head of the pump is determined by the sum of the head losses on all elements of the circulation loop.

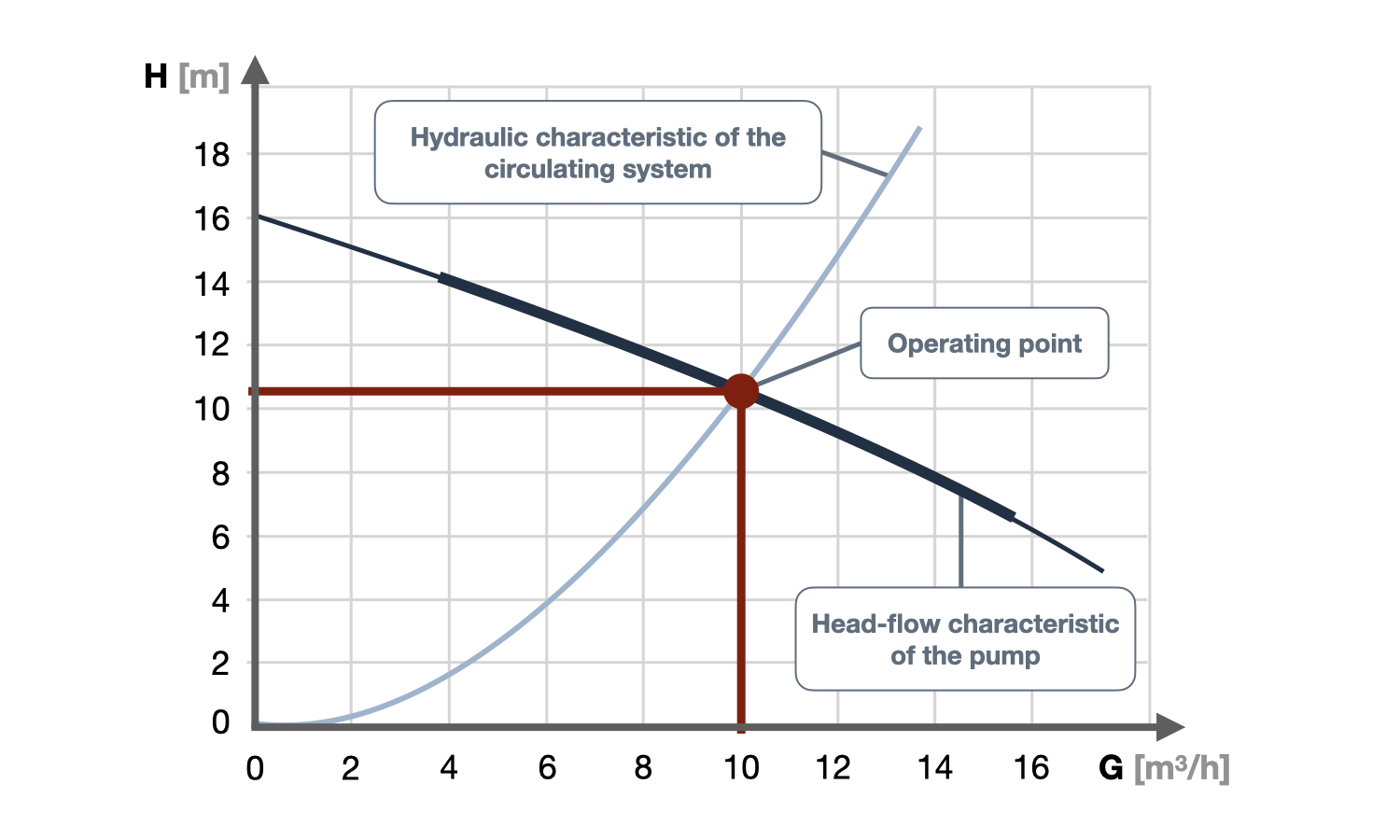

Head-flow characteristic curve — a graphical representation of the dependence of the head of a centrifugal pump on its flow rate. Low-speed pumps with a rotation frequency below 1500 rpm have a flatter characteristic curve, meaning that the head generated by the pump changes less significantly with changes in flow rate compared to high-speed pumps.

Hydraulic characteristic curve of the network — a graphical representation of the dependence of the head losses in the network (circulation loop) on the water flow rate. The hydraulic characteristic curve of the network has a parabolic shape since the change in head losses in the circulation loop is equal to the square of the change in water flow rate.

Operating point of a pump — the point of intersection between the pump's performance curve and the system curve. The working point determines the flow rate and head of the pump when it is connected to the system (circulation loop). The head always equals the system resistance, and the flow rate can be determined by dropping a perpendicular from the working point to the flow rate axis (abscissa).

Suction lift — Ns [m] — the difference in elevation between the centerline of the impeller and the liquid level in the lower reservoir, accounting for head loss in the pipeline that connects the lower reservoir to the pump and assuming that the water in the lower reservoir is at atmospheric pressure.

The water is lifted from the lower reservoir by the difference in pressures, creating a low pressure zone in the impeller of the pump and a high pressure on the water due to atmospheric pressure. Since atmospheric pressure corresponds to a water column of 10.3 meters, and the pump cannot create an absolute vacuum in the impeller, the suction lift of the pump cannot be greater than 8 meters.

Net Positive Suction Head (NPSH) — the minimum pressure in the suction line of the pump that ensures cavitation-free operation. The value of the NPSH is determined experimentally by pump manufacturers and is presented in the form of a graph showing the relationship between the pump flow rate and NPSH.

Pump power output — Nu [W] — is determined by the total energy delivered to the liquid per unit time.

Nu = ρ • g • Q • H

Pump mechanical power — Nw [W] — the mechanical power transferred to the shaft. The mechanical power is higher than the useful power by the amount of hydraulic losses and losses due to friction in the impeller.

Nw = Nu / η

Pump efficiency — η [%] — the coefficient that characterizes the degree of efficiency of the pump and is determined as the ratio of the useful power to the power on the shaft.

Energy efficiency class — [A-G] — the generally accepted classification of consumer goods reflecting their energy efficiency. Energy efficiency classes are designated by Latin letters from A to G. Products marked with A have the lowest energy consumption, while those marked with G have the highest.

Comparing pumps with similar hydraulic characteristics of different energy efficiency classes, it can be established that the energy consumption difference between pumps of two adjacent classes is 22%. A pump of class A uses only about 33% of the energy required for the operation of a class D pump.

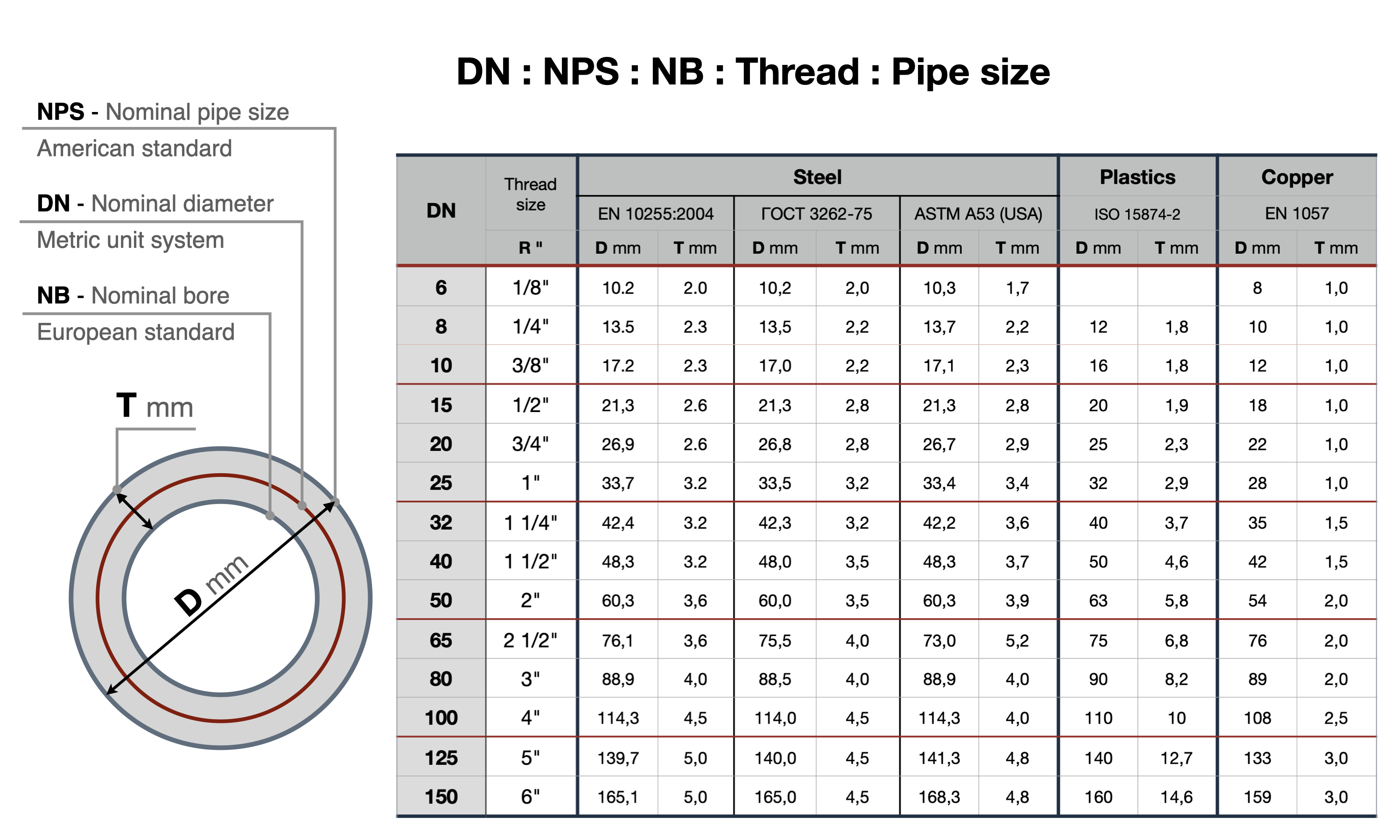

Nominal diameter — DN — numeric designation of the internal diameter of the pump's connecting flanges, which is common for all pipeline elements. The nominal diameter of the pump has no dimension, but its value is approximately equal to the internal diameter of the connected pipeline.

Nominal pressure — PN — the maximum excess water pressure at a temperature of 20°C, at which the pump is allowed to operate continuously.

question : comment : feedback

808

Tutorial Grundfos

Tutorial Grundfos Catalog of

Catalog of