Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Design of the check valve

Lift check valve - equipped with a disc shut-off element. The disc blocks the flow by seating onto the valve seat. The axis of the disc movement coincides with the flow axis.

As soon as the force of the flow under the disc exceeds the spring force that holds it closed, the disc lifts and opens the passage. When the medium is supplied above the disc, the flow vector aligns with the spring force vector, keeping the disc closed.

Lift check valves are spring-loaded, and in some modifications, they may be additionally equipped with a lever mechanism.

The body of a lift check valve is made of cast iron or steel. They are heavy and bulky but are reliable, not demanding of the medium quality, and effectively seal against reverse flow. Lift check valves are typically installed in heating systems, industrial facilities, and boiler houses. Spring-loaded check valves are recommended for installation in locations with high flow turbulence.

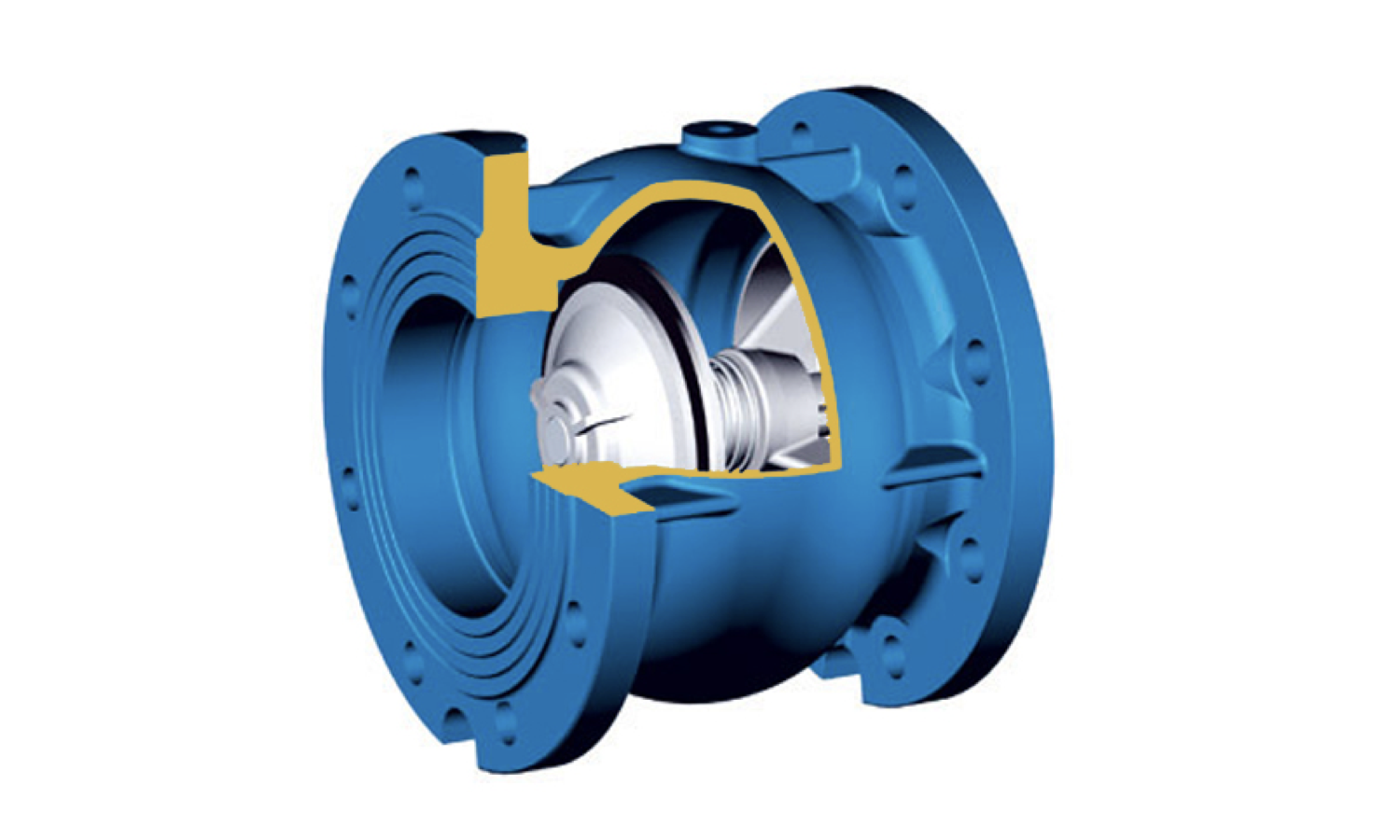

Swing check valve — the shut-off element consists of a steel disc, and the flow is blocked by seating the disc onto the valve seat. Upon opening, the disc moves radially relative to the flow axis.

Swing check valves are highly reliable, provide a tight seal, and have good flow capacity, but like lift valves, they are metal-intensive and bulky. Since the disc closes by gravity, swing valves can only be installed on horizontal pipelines or on vertical pipelines with an upward flow direction.

Some designs of swing check valves allow for the optional installation of a lever mechanism for closing.

Swing check valves are installed in industrial facilities, heating networks, large heat points, and boiler houses.

Ball check valve — its shut-off element is a polymer, rubber, or vulcanized cast iron ball, which blocks the passage by its own weight. In forward flow, the ball moves into a chamber located outside the flow passage, and when the flow stops or reverses, the ball blocks the passage.

The body of the ball valve is made of cast iron, and the connection to the pipeline can be either threaded or flanged.

Ball check valves are used in water supply and drainage systems, as well as pipelines transporting viscous or contaminated liquids. Ball check valves have low hydraulic resistance but, like the previous designs, they are heavy and bulky.

The installation of a ball check valve is only allowed on horizontal pipelines or vertical ones with an upward flow direction.

Disc check valve - the shut-off element of this valve is a steel disc, whose movement axis coincides with the pipeline axis. Flow is blocked by seating the disc onto a fixed seat. In some designs, a polymer sealing ring is installed in the disc or seat to improve sealing.

The disc is held in place by a spring, so it remains closed until the force of the forward flow on the disc exceeds the spring force. In the open position, the disc remains in the flow passage, and the flow passes through gaps between the disc and the valve body.

Compared to the previous designs, disc check valves are lighter, smaller, but they create significant hydraulic resistance, and they require removal from the pipeline for repairs.

The installation of a disc valve is allowed in any position. They are used in boiler houses, heat points, and heating and water networks.

question : comment : feedback

210

Catalog of

Catalog of сheck valves

Zetkama

Zetkama

Genebre

ГОСТ

Danfoss

CMO

CMO

CMO

Honeywell - Resideo

Ukspar

Hawle

Brandoni

Brandoni

Brandoni

IVR

ARI Armaturen

FAF

Oventrop

Polix

Polix

Polix

AVK

AVK

EN 1092-1

EN 1092-1