Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

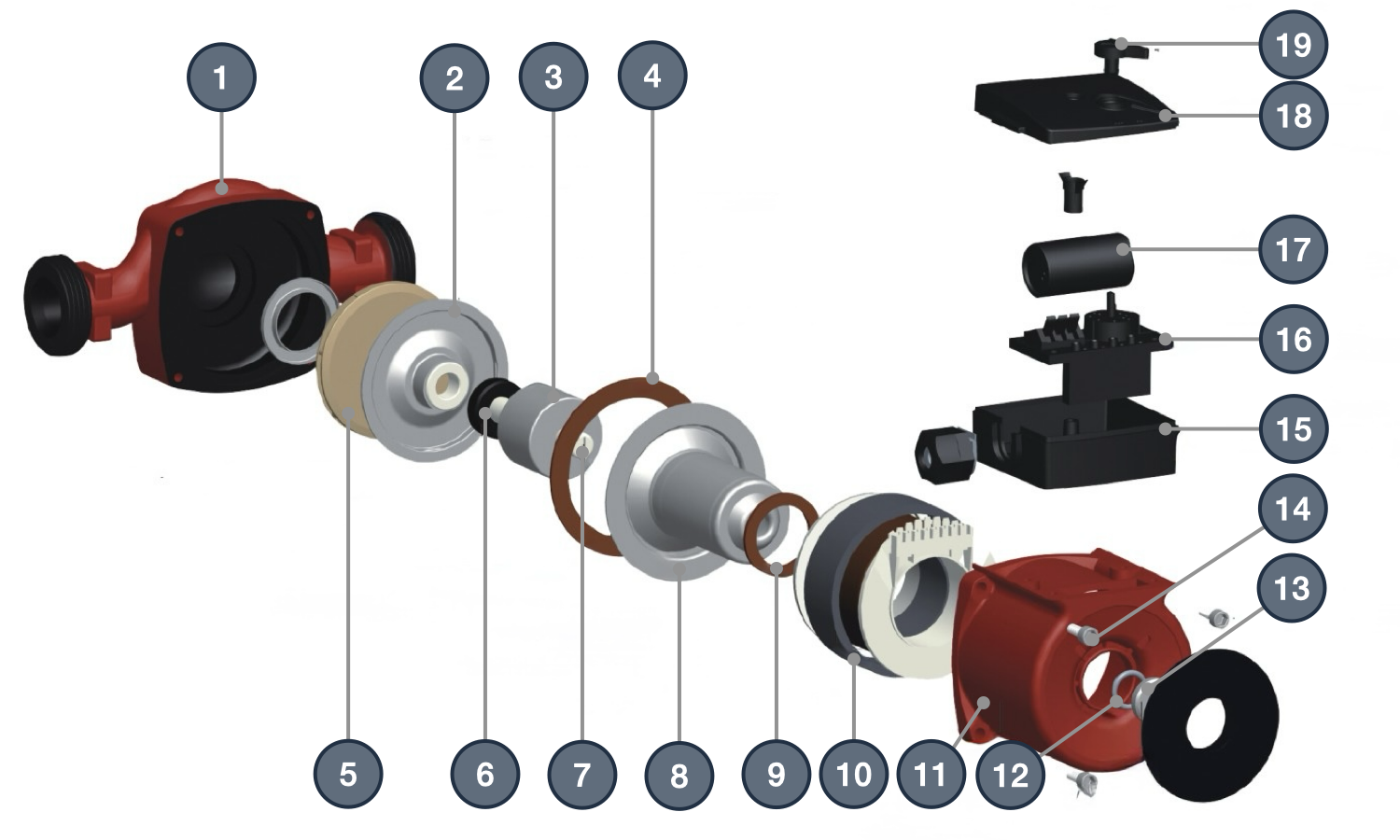

The design of the circulation pump

- 1 - Pump body

- 2 - Stainless Steel Cover

- 3 - Rotor

- 4 - Gasket

- 5 - Impeller

- 6 - Thrust bearing

- 7 - Ceramic Shaft

- 8 - Stainless Steel Shielding

- 9 - Sealing ring

- 10 - Stator

- 11 - Housing

- 12 - O-ring Rubber

- 13 - Exhaust Screw

- 14 - Screw

- 15 - Terminal box base

- 16 - Junction box

- 17 - Capacitor

- 18 - Cover

- 19 - Speed control rotary knob

- 20 - Screw

The construction of the circulation pump is shown using the example of a centrifugal pump with water-cooled motor 'wet rotor'.

A closed composite impeller is mounted on the motor shaft in a cast iron housing.

The impeller consists of two parallel discs connected by radially bent blades. One of the discs has an inlet for the working fluid, and the other has a hole for attaching the impeller to the motor shaft.

The housing of the pump has a spiral-shaped diffuser opening around the periphery of the impeller, necessary to convert the kinetic energy of the flow into static pressure, as well as for collecting and discharging water in the desired direction.

The impeller is attached to the rotor shaft, which is washed and cooled by the pumped water. The energized stator of the motor is hermetically separated from the rotor by a separator cup. The cup is made of non-magnetic stainless steel or carbon fiber with a wall thickness of 0.1-0.3 mm.

The rotor of the circulation pump is mounted on end-face sliding bearings made of ceramics or graphite. The bearings are cooled by the pumped water.

The external feature of a wet rotor circulation pump that distinguishes it from pumps with air-cooled motors is the absence of fins on the surface of the electric motor and a fan on its end face.

The construction of a wet rotor circulation pump is more complex than that of pumps with air-cooled motors, so the price of such a pump will be higher for the same flow characteristics.

question : comment : feedback

281

Catalog of

Catalog of circulation pumps

DAB

DAB

DAB

DAB

Wilo

Wilo

Wilo

Wilo

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

Calpeda

Calpeda

Calpeda

Calpeda

Calpeda

Grundfos

Wilo

Wilo

Wilo

Wilo

Wilo

Calpeda

Calpeda

Grundfos

Grundfos

Grundfos

Grundfos

Grundfos

DAB

DAB

Smedegaard

Smedegaard

Smedegaard

Lowara

Lowara

Lowara

Lowara

Lowara

IMP Pumps

Tutorial Grundfos

Tutorial Grundfos