Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

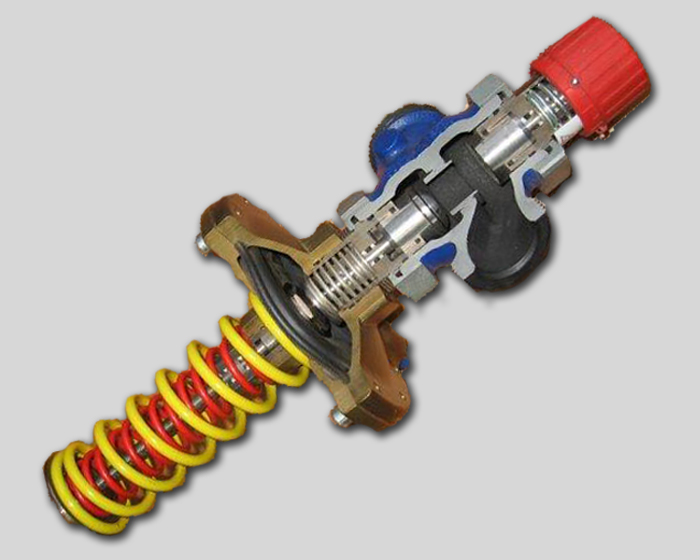

Construction of a water pressure regulator

Direct Acting Pressure Regulator

A direct acting pressure regulator does not require external sources of energy, using only the excess pressure of water to maintain the desired pressure level. These are proportional regulators, in which valve opening corresponds to deviation of the controlled variable, and the opening speed corresponds to the rate of pressure change.

The mandatory elements in the pressure regulator design are:

- Actuator — spring, pneumatic or lever-loaded mechanism

- Impulse line — external or embedded in the valve body

- Sensing element — diaphragm, bellows or piston

- Control element — seat valve with linear stem displacement

Membrane Pressure Regulator — a regulator with a spring actuator and a membrane sensing element, characterized by high pressure maintenance accuracy, reliable construction and reparability, though at a higher price than a spring construction. Membrane regulators are used in boiler rooms, thermal substations, and residential water supply systems.

Membrane pressure regulators:

Spring pressure regulator is a regulator with a spring-loaded setting mechanism, where the valve closure element serves as the measuring element. The construction of a spring pressure regulator is simpler and less expensive than a similar membrane pressure regulator, while maintaining high accuracy of pressure control. Typically, spring pressure regulators are used at the entrance of water supply to an apartment.

Pressure regulators of spring construction:

By appointment, similar devices can be called:

- Pressure regulator 'after oneself' — Reduction valve.

- Pressure regulator 'before oneself' — some types of By-pass valves.

Indirect Acting Pressure Regulator

The design of an indirect acting pressure regulator assumes the connection of an external energy source. The mandatory elements in the design of the regulator are:

- Measuring element — pressure sensor

- Control device — programmable controller

- Actuator — control valve with electric actuator

Advantages of indirect acting pressure regulators:

- Wide range of maintained pressures

- High accuracy of pressure control

- Remote control

- Possibility of selecting a valve of a large diameter

- Possibility of changing the reaction to a controlled parameter deviation

- Large distances between the pressure maintenance site and the control valve

Disadvantages of indirect acting pressure regulators:

- Dependence on an external energy source

- High cost compared to direct acting regulators

- Less reliable construction compared to direct acting regulators

Indirect acting pressure regulators can be assembled based on any control valve and practically any pressure sensor and controller.

question : comment : feedback

224

Catalog of

Catalog of pressure reduction controllers

Danfoss

Danfoss

Danfoss

Honeywell - Resideo

ARI Armaturen

LDM

LDM

Gestra

Samson

Samson

Samson

КПСР Групп

IMI Hydronic

IMI Hydronic

Samson

RTK

RTK

Termen

Termen

Tutorial Herz

Tutorial Herz