Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

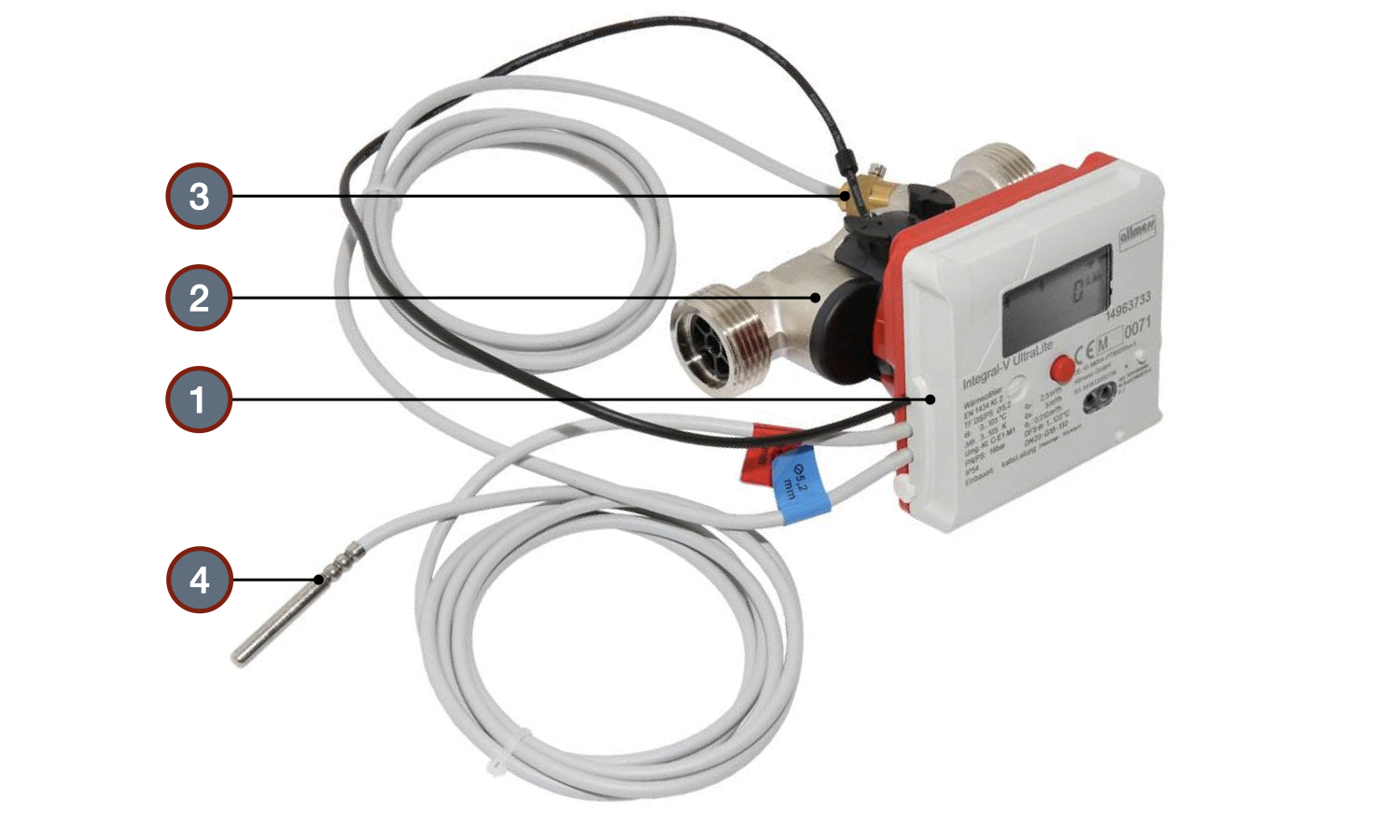

Construction of a heat meter

- 1 - Calculator

- 2 - Ultrasonic flow meter

- 3 - Water temperature sensor built into the flow meter

- 4 - Water temperature sensor

The simplest design of a heat meter includes a flow sensor, two temperature sensors, and a calculator.

Calculator

The types of calculators used with industrial and residential heat meters differ only in the set of functions, depth of archive, and availability of additional data transfer modules.

Calculators for industrial heat meters can have autonomous or external power supply, while calculators used in residential heat meters are equipped with a battery with a service life of at least 5 years.

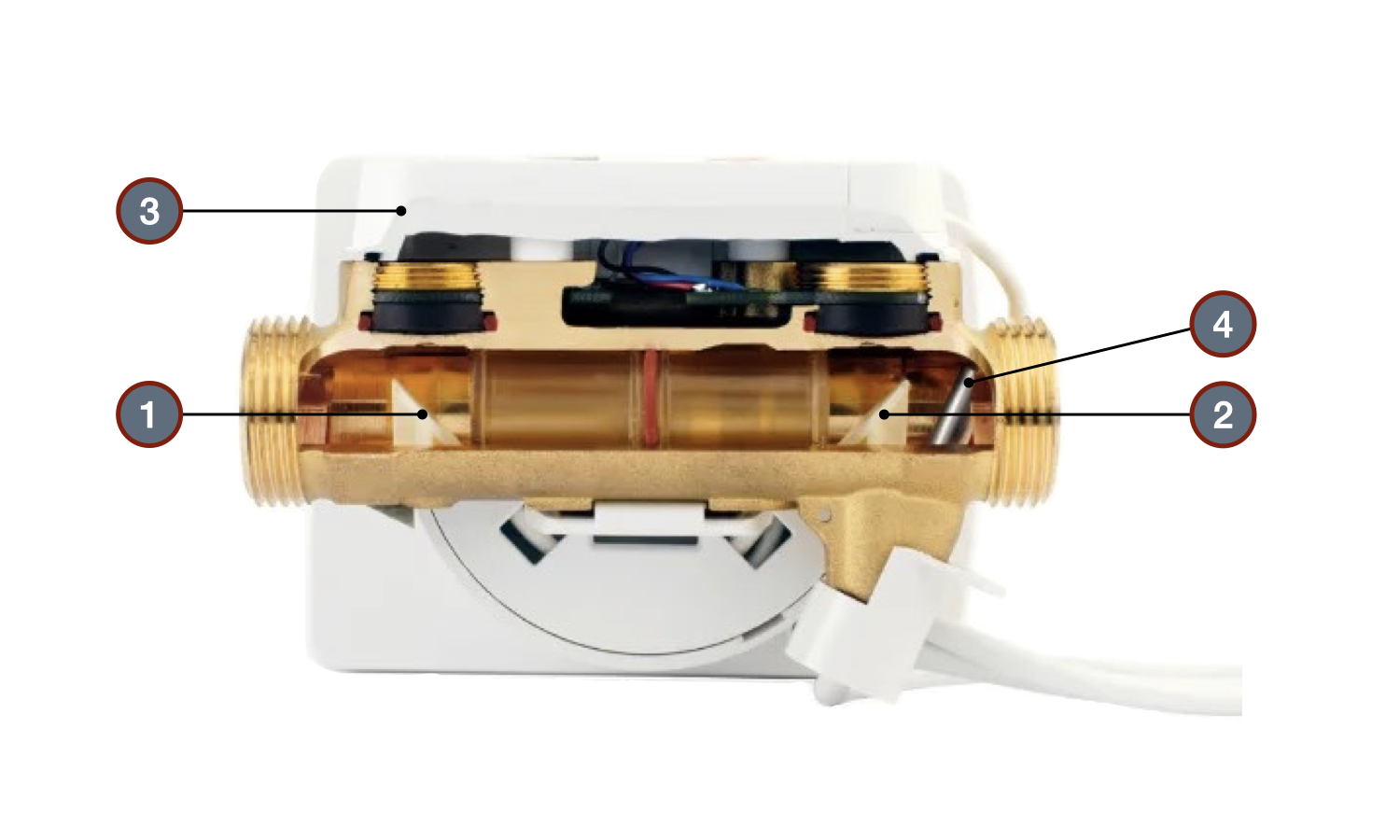

Flow Sensor

- 1 - Ultrasonic signal emitter

- 2 - Ultrasonic signal receiver

- 3 - Electronic calculator

- 4 - Built-in temperature sensor

Ultrasonic heat meter - a device for measuring heat energy based on an ultrasonic flow meter. It is distinguished by high reliability, low sensitivity to the quality of the heat carrier, and negligible hydraulic resistance.

Ultrasonic heat meters are characterized by high accuracy even at very low flow rates and a wide dynamic range, which allows apartment owners to significantly expand the range of regulation when reducing heat consumption.

The ultrasonic heat meter does not have any moving parts in the flow part. Its flow meter is made in the form of a smooth tube in which two ultrasonic sensors are installed, one of which sends an ultrasonic signal, and the other receives it. The time of ultrasound passage in the moving and stationary flow is different, and the calculator measures the time of ultrasound signal passage from the transmitter to the receiver and, based on the obtained values, determines the flow rate.

At present, ultrasonic heat meters are the most modern and reliable devices for residential heat metering, which have practically displaced mechanical meters from the European market.

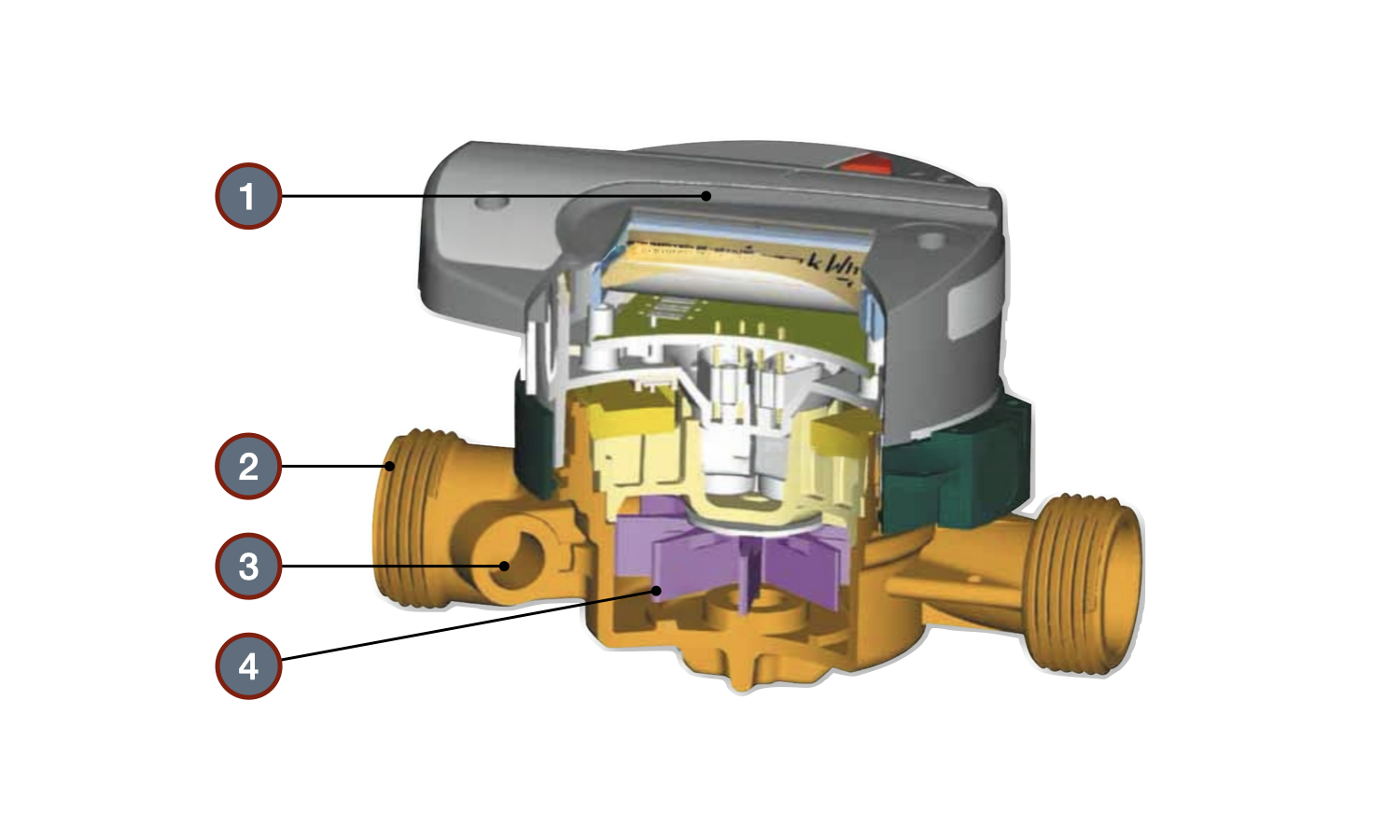

- 1 - Electronic calculator

- 2 - Mechanical flow meter

- 3 - Opening for temperature sensor

- 4 - Rotating impeller wheel

Mechanical heat meter - a device for measuring thermal energy based on a mechanical flow sensor. It is characterized by low cost, relatively high hydraulic resistance and the presence of moving parts in the flow section.

A paddlewheel rotor is installed in the flow section of the mechanical flow sensor, and its rotation is transmitted to the counting mechanism. The calculator determines the amount of water that has passed through the heating system based on data on the frequency of the paddlewheel rotation. A mesh filter is always installed before the mechanical flow sensor to protect it from damage by large abrasive particles.

Compared to ultrasonic devices, mechanical heat meters have less reliable construction, smaller dynamic range, and non-removable connection to the calculator, which can complicate reading the measurements in some cases.

Temperature sensor

The construction of a heat meter may include various temperature sensors, such as Pt100, Pt500, Pt1000, or Pt10000. A temperature sensor is a platinum thermoresistor that has a rigid dependence of electrical resistance on temperature, and the numbers 100, 500, 1000, and 10000 indicate its resistance in ohms at 0 °C.

Single and modular construction

Modular heat meters are used for industrial purposes and large commercial accounting, in which each device is ordered separately and can be replaced later. The modularity of the design allows for the most flexible selection of heat meter components to solve specific tasks.

For residential accounting purposes, single-construction heat meters are used, in which the calculator, temperature sensors, and flow sensor are non-removably connected at the manufacturer's plant. Single-construction meters are usually cheaper than modular ones.

question : comment : feedback

306

Catalog of

Catalog of compact heat meters

Zenner

Landis Gyr

Landis Gyr

Gross

Engelmann

Engelmann

DIEHL

Kamstrup

Apator

Sensus

Maddalena

Sontex

Sontex

Sontex

Itron

Itron

Landis Gyr

Kamstrup

Sontex

DIEHL

Sensus

Engelmann

Apator

Itron

Maddalena

EN 1092-1

EN 1092-1