Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Adjustment of Centrifugal Pump Flow Rate

There are three ways to regulate the performance of a pump:

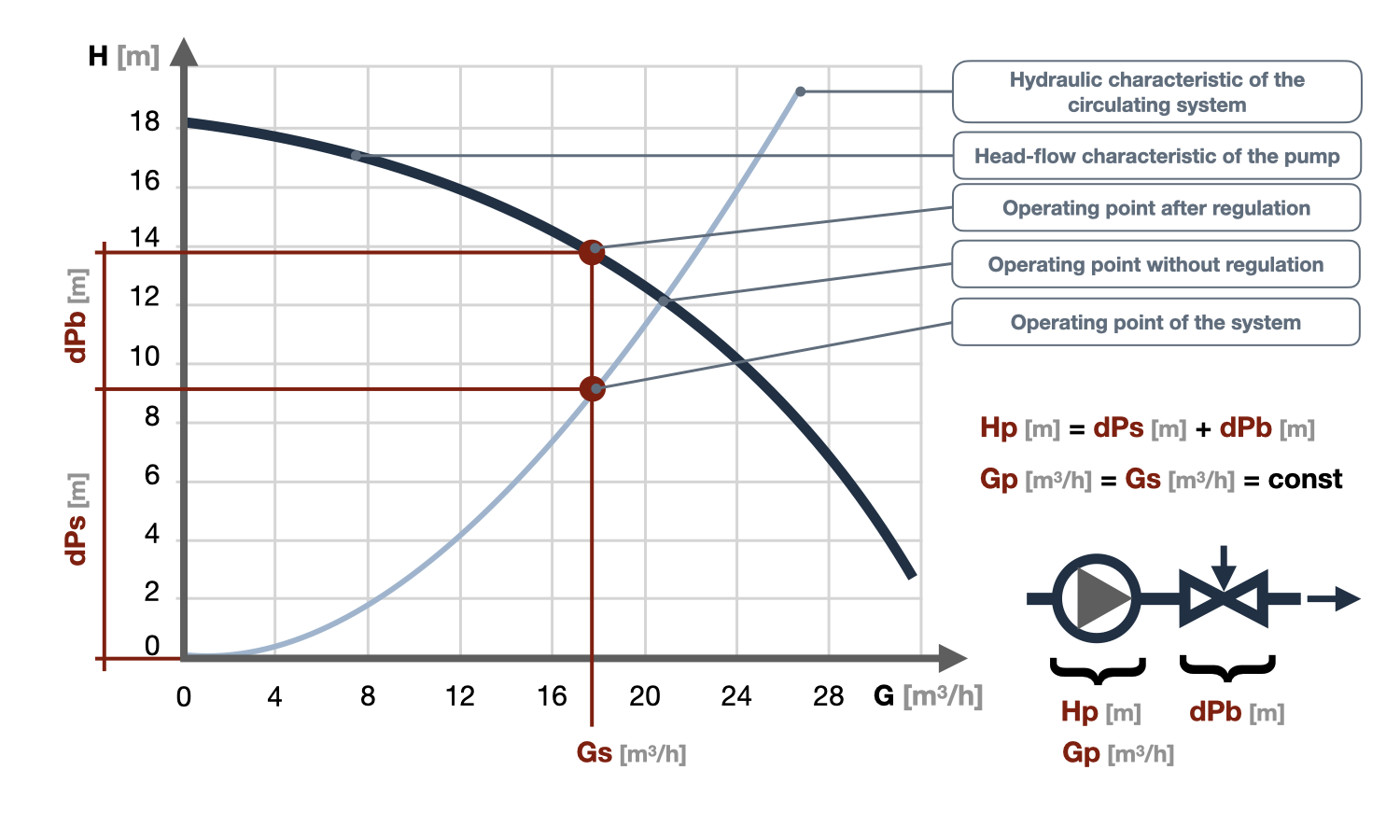

Throttling - the simplest and least effective way to regulate the flow of a centrifugal pump. To throttle the flow, the hydraulic resistance of the system is increased.

Automatic or manual control valves can be used for flow throttling or a throttling disk can be installed.

During pump flow throttling, the operating point moves up the head-flow curve, increasing the head while reducing the flow rate and efficiency.

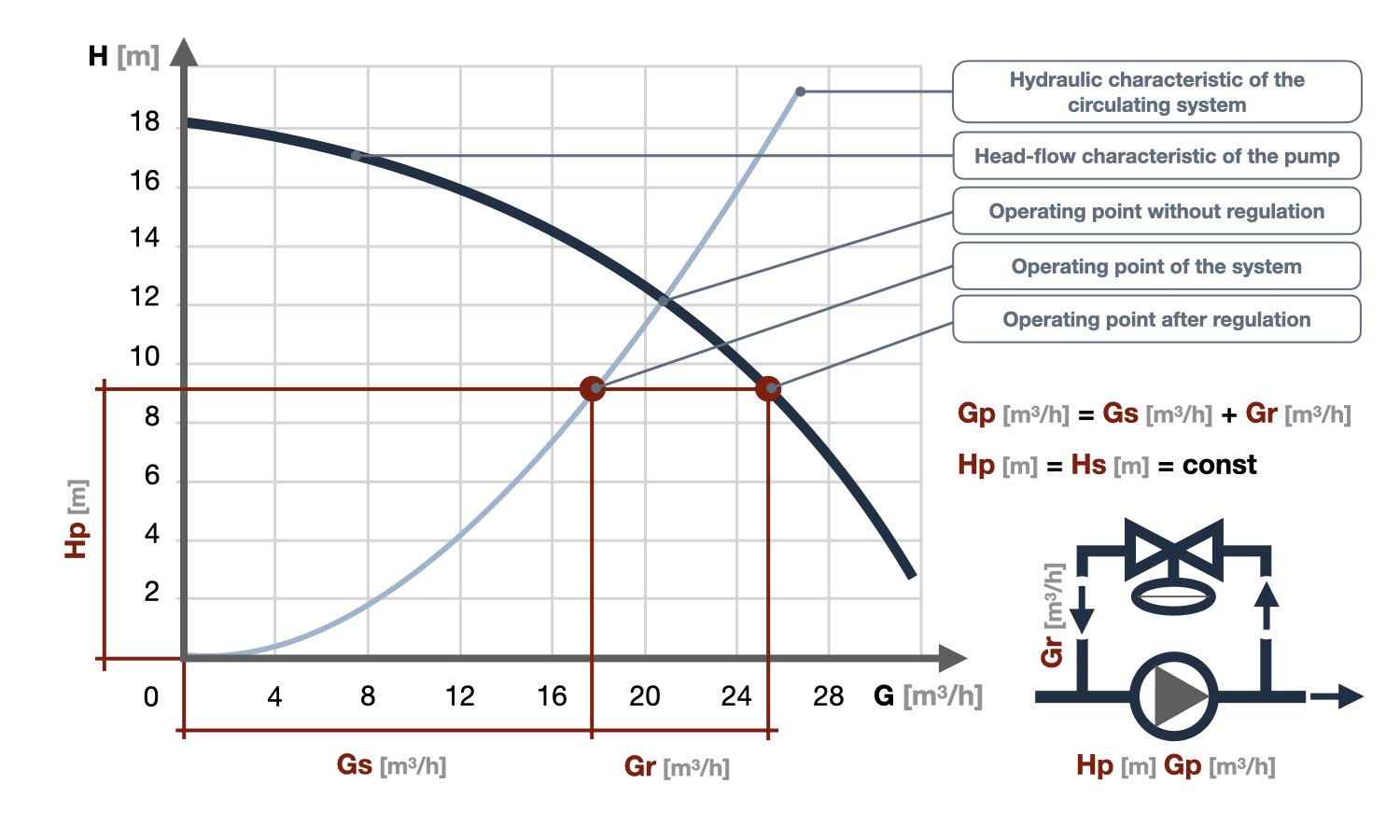

Bypass regulation - to regulate the productivity at the juncture between the inlet and outlet pipes of the pump, a regulator is installed that maintains a constant pressure drop at the pump (constant pump head). When the pump flow is reduced, the head created by it increases - the regulator responds to deviations from the set point and opens, bypassing water from the discharge pipe into the suction pipe. Thus, the pump flow remains unchanged, and the water flow rate in the network can fluctuate widely.

The advantage of this regulation method is that the pump always operates with a constant flow rate and head in the zone of optimal efficiency, while the disadvantage is that the consumption of electrical energy remains unchanged when the load in the consumption network decreases.

Bypass pump flow regulation is used in heating systems with automatic regulating valves that change the consumption depending on the building's heat needs, as well as to activate pumps that do not allow strong flow fluctuations in systems with dynamic hydraulic regimes.

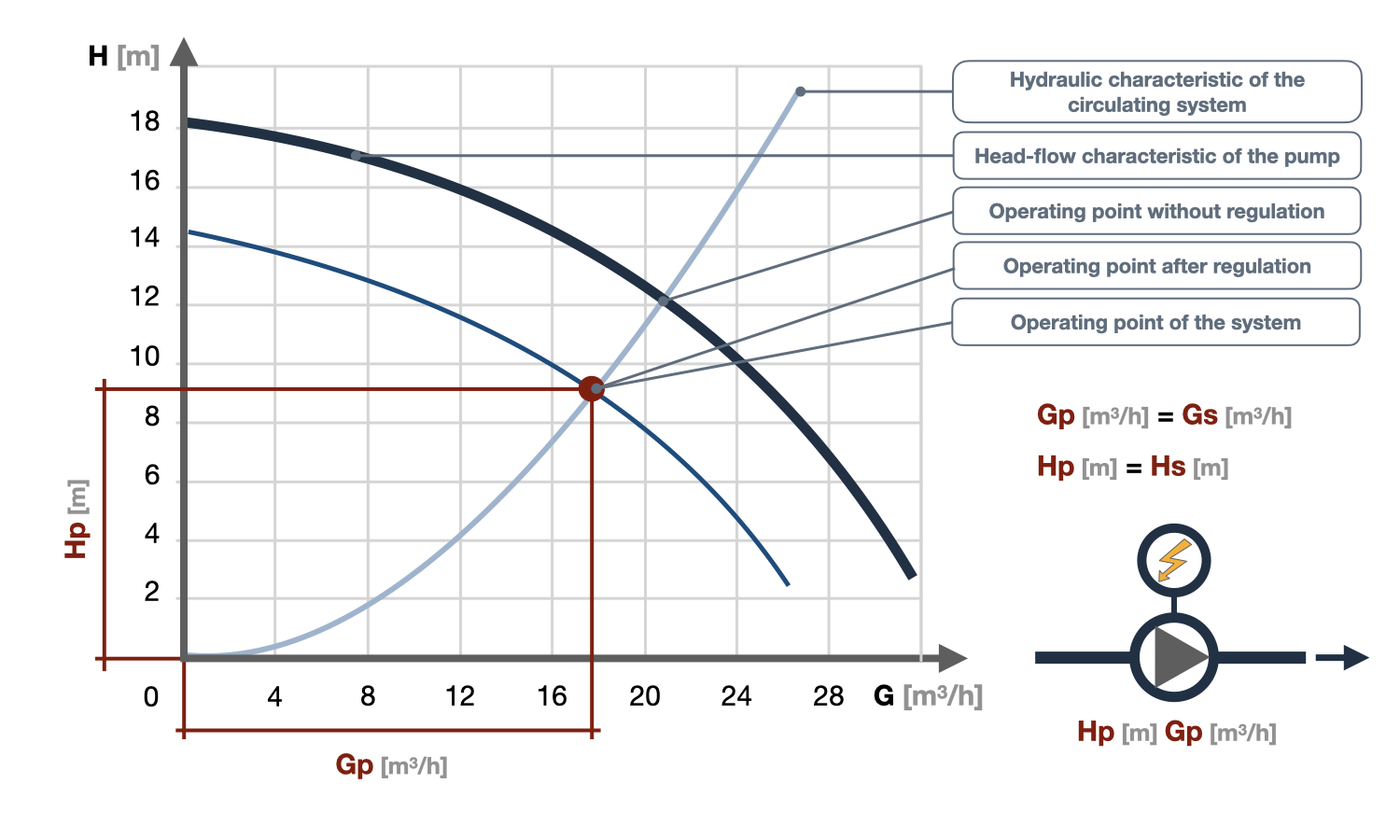

Frequency control - installing a frequency controller is the most efficient and expensive method of pump flow control since the cost of the frequency regulator is comparable to the cost of the pump.

The physics of this method is simple: by halving the frequency of the pump's impeller rotation, the flow rate is reduced by half, the head is reduced by four times, and the electrical energy consumption is reduced by eight times.

Modern frequency controllers can maintain a constant pump flow rate or head or change them depending on the system's needs at different times of the day or week.

Programmable control will not only ensure the pump operates at maximum efficiency but also reduce noise during operation, provide a soft start, reduce starting current, and prevent hydraulic shock.

Frequency control of the centrifugal pump flow rate change by changing the motor speed is reasonable in systems with frequent and strong water consumption fluctuations and in case of high electricity costs. In such systems, the costs of the frequency controller can be recouped in a few months.

question : comment : feedback

490

Tutorial Danfoss

Tutorial Danfoss Catalog of

Catalog of