Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Regulation of circulation pump flow

Throttling method — the simplest and least effective way to regulate the pump flow. The operating point moves up along the pump characteristic curve, and at zero flow, it coincides with the ordinate axis, while the pump operates at low efficiency.

The throttling device can be a manual balancing valve, a regulating valve with an electric drive, a pressure regulator, or a throttle diaphragm.

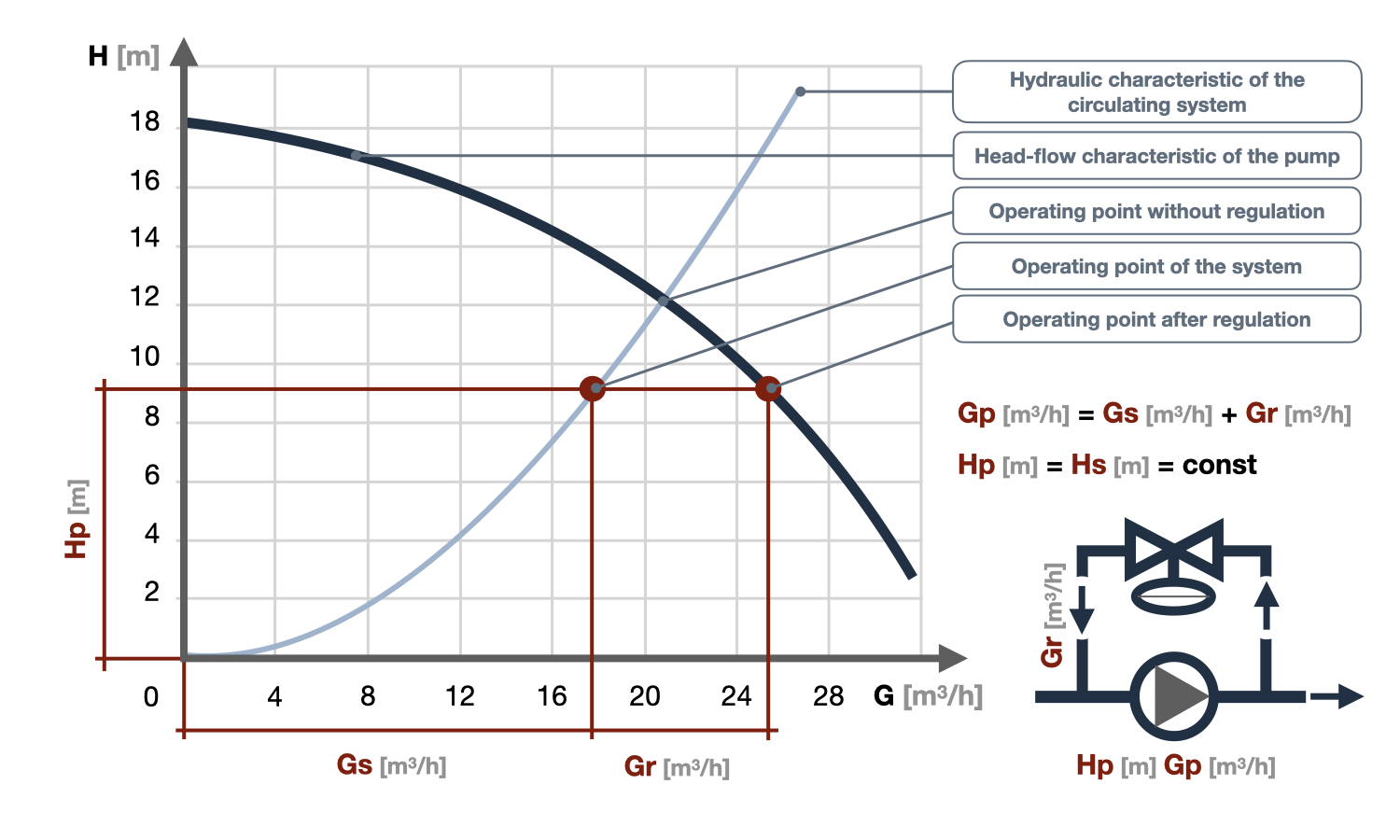

Bypass method — implemented by installing a bypass valve or a pressure differential regulator in the bridge between the pump's discharge and suction ports, which opens when the controlled variable increases. The pump operates at the point on the head-flow characteristic curve that corresponds to the set pressure drop (pump head), and the excess flow is bypassed from the suction port to the discharge port through the bypass line.

This type of regulation is often used to protect pumps that cannot operate at low flows in heating systems with radiator thermostatic valves. Closing the radiator valves reduces the flow rate in the heating system, causing the pump head to increase and the bypass valve to open, allowing the heat carrier to bypass from the discharge port to the suction port, thereby maintaining a constant flow rate through the pump.

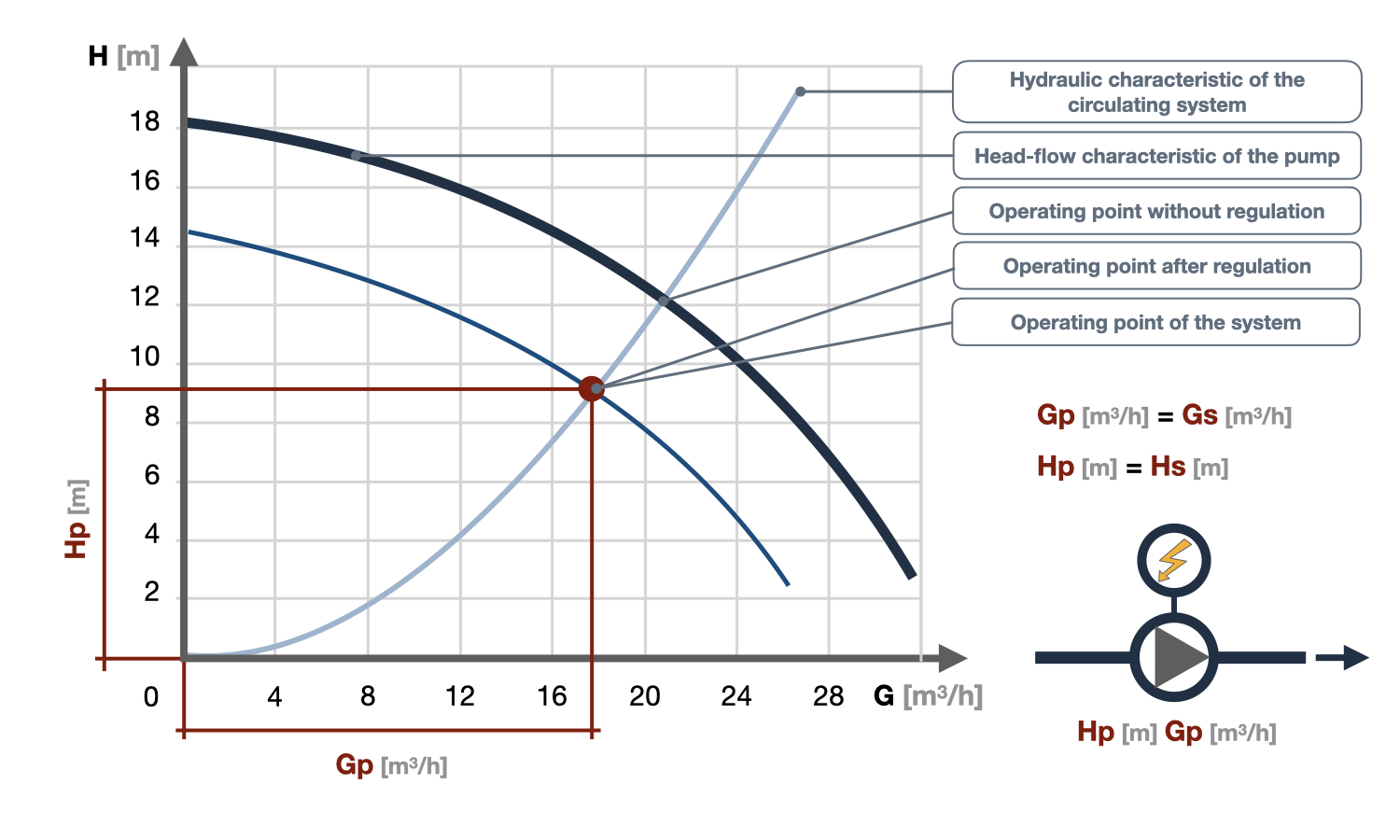

When regulating by changing the rotational speed of the impeller — the pump flow rate changes in proportion to the change in rotational speed, the pump head — in proportion to the square of the change in rotational speed, and the changes in power consumption — in proportion to the cube of the change in rotational speed.

Software control of the impeller rotational speed not only ensures the pump operates at maximum efficiency over a wide range of flow rates, but also reduces noise generated during operation, implements a soft-start function, reduces starting currents, and eliminates hydraulic shocks in systems.

question : comment : feedback

342

Catalog of

Catalog of circulation pumps

DAB

DAB

DAB

DAB

Wilo

Wilo

Wilo

Wilo

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

IMP Pumps

Calpeda

Calpeda

Calpeda

Calpeda

Calpeda

Grundfos

Wilo

Wilo

Wilo

Wilo

Wilo

Calpeda

Calpeda

Grundfos

Grundfos

Grundfos

Grundfos

Grundfos

DAB

DAB

Smedegaard

Smedegaard

Smedegaard

Lowara

Lowara

Lowara

Lowara

Lowara

IMP Pumps

Tutorial Danfoss

Tutorial Danfoss