Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

How do District Heating Substation work

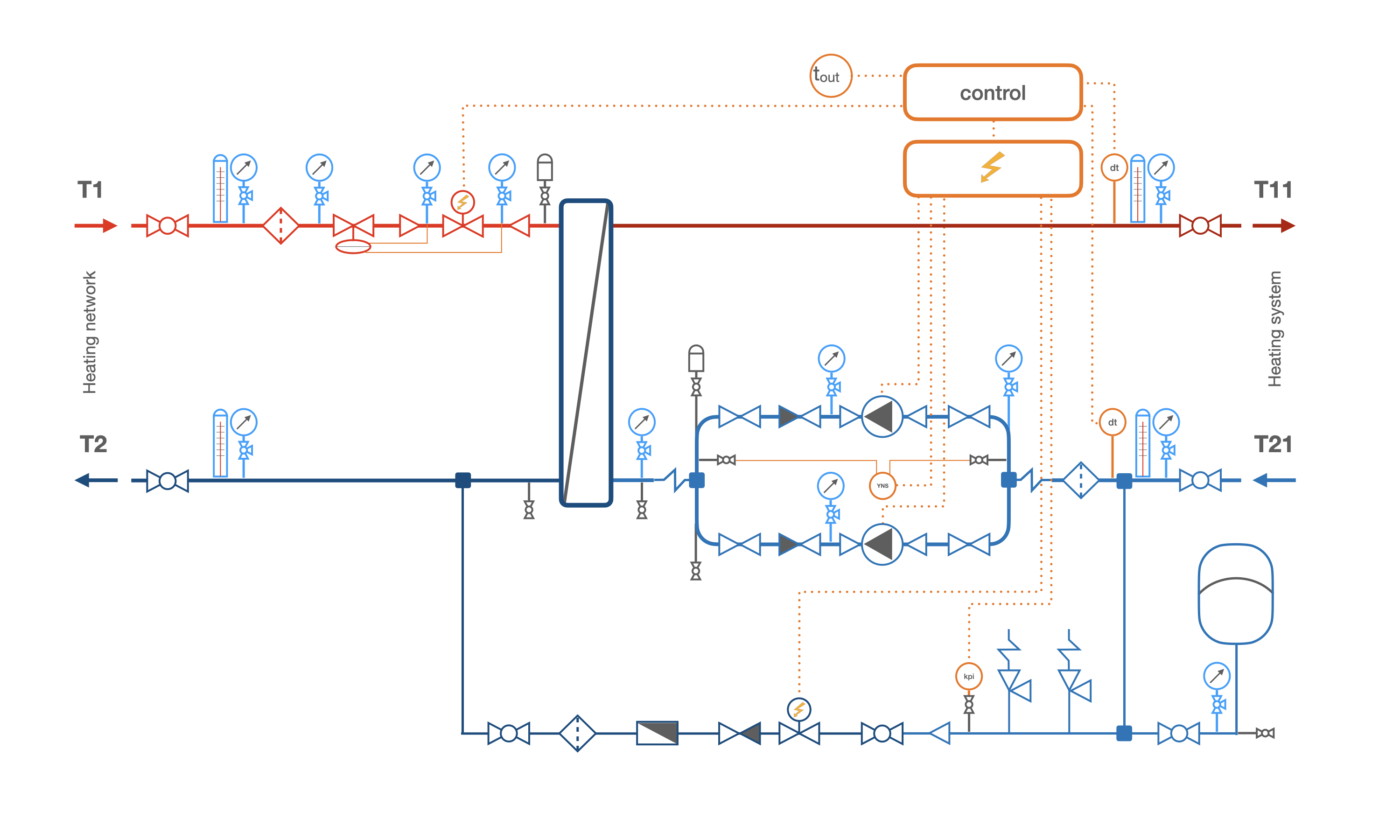

District heating substation connected with an independent scheme

In the district heating substation connected with an independent scheme, the hydraulic circuit of the heating system is separated from the hydraulic circuit of the heat source by a heat exchanger. The heat transfer fluid circulating in the heating system comes into contact with the hot water from the heat source only through heat exchange surfaces, without mixing.

The operation of the district heating substation is controlled by an electronic programmable controller equipped with an outdoor air temperature sensor, a temperature sensor of the heat transfer fluid entering the heating system, and an electrically actuated regulating valve capable of partially or completely shutting off the supply of heat transfer fluid at the heat source inlet.

A table of dependence of the water temperature entering the heating system on the outdoor air temperature, called the temperature regime, is entered into the controller. The program can be configured to reduce the temperature of the heat transfer fluid by a certain value according to the temperature schedule, depending on the day of the week and time of day, which is often used in buildings with a fixed operation schedule, such as schools, offices, and production facilities.

The controller periodically measures the outdoor air temperature, determines the corresponding temperature of the heat transfer fluid at the inlet to the heating system, and compares it with the actual value of this temperature according to the signal from the corresponding sensor. If the temperature of the water entering the heating system exceeds the set value, the controller sends a signal to control the electric actuator to close the regulating valve and shut off the supply of heating fluid to the heat exchanger. If the temperature is below the set value, the actuator of the regulating valve receives an opening signal.

If the flow of heating medium is completely shut off, water taken from the return pipeline of the heating system passes through the heat exchanger without heating and returns to the system with the same temperature. The more the regulating valve is open, the more heating medium enters the heat exchanger and the more the heating medium that enters the heating system is heated.

Circulation in the heating system circuit is provided by two circulation pumps, one of which is a backup.

A pressure differential controller is installed at the entrance to the heat network before the regulating valve, which stabilizes the pressure difference at the entrance and is used to limit the flow rate of the heating medium.

The increase in the volume of water formed during heating in a closed heating system circuit is absorbed by expansion tanks, which return the accumulated water back to the system during the next cooling.

To protect the heating system and the equipment of the heating substation from exceeding permissible pressure values, a safety valve is installed.

Filling and replenishing of the closed heating system circuit in case of leakage is carried out manually or in automatic mode through a supply line. If the pressure at the inlet from the heat source is sufficient for filling the system, a solenoid valve or a pressure reducing regulator is used on the supply line, and in case of insufficient pressure at the inlet, a block of supply pumps is used.

Advantages of independent connection of the district heating substation:

1 Protects the heating system from high pressure in the district heating network.

2 Allows for the desired hydraulic regime to be created in the heating system circuit.

3 Eliminates the need to drain the heating system during draining of the heat source pipelines and during low input pressure.

4 Protects heating system components from sludge that enters with the flow of the heating medium from the heat source.

Disadvantages of independent connection schemes for heating substations:

1 The temperature of the heating medium that enters the heating system will always be at least 10°C lower than the temperature of the heating medium that comes from the district heating network. In a fast heat exchanger, the temperature of the heated water cannot reach the temperature of the water that heats it.

2 The higher cost of a heating substation with an independent connection compared to a heating substation of similar capacity but with a dependent connection. The difference is almost twice as much.

3 The pressure in the heating system changes when the heating medium is heated or cooled. At the minimum (design) temperature, the pressure in the heating system reaches the accepted maximum value, while in warm days of the heating period, the pressure reaches the minimum value, which equals the static pressure of the heating system with a slight excess pressure.

4 The startup, configuration, and maintenance of an independent connection scheme heating substation is more complex compared to heating substations connected with a dependent scheme.

5 The circulation of water in the heating system will stop if the pumps are switched off.

Types of independent connection schemes for heating substations and in which cases they are applied.

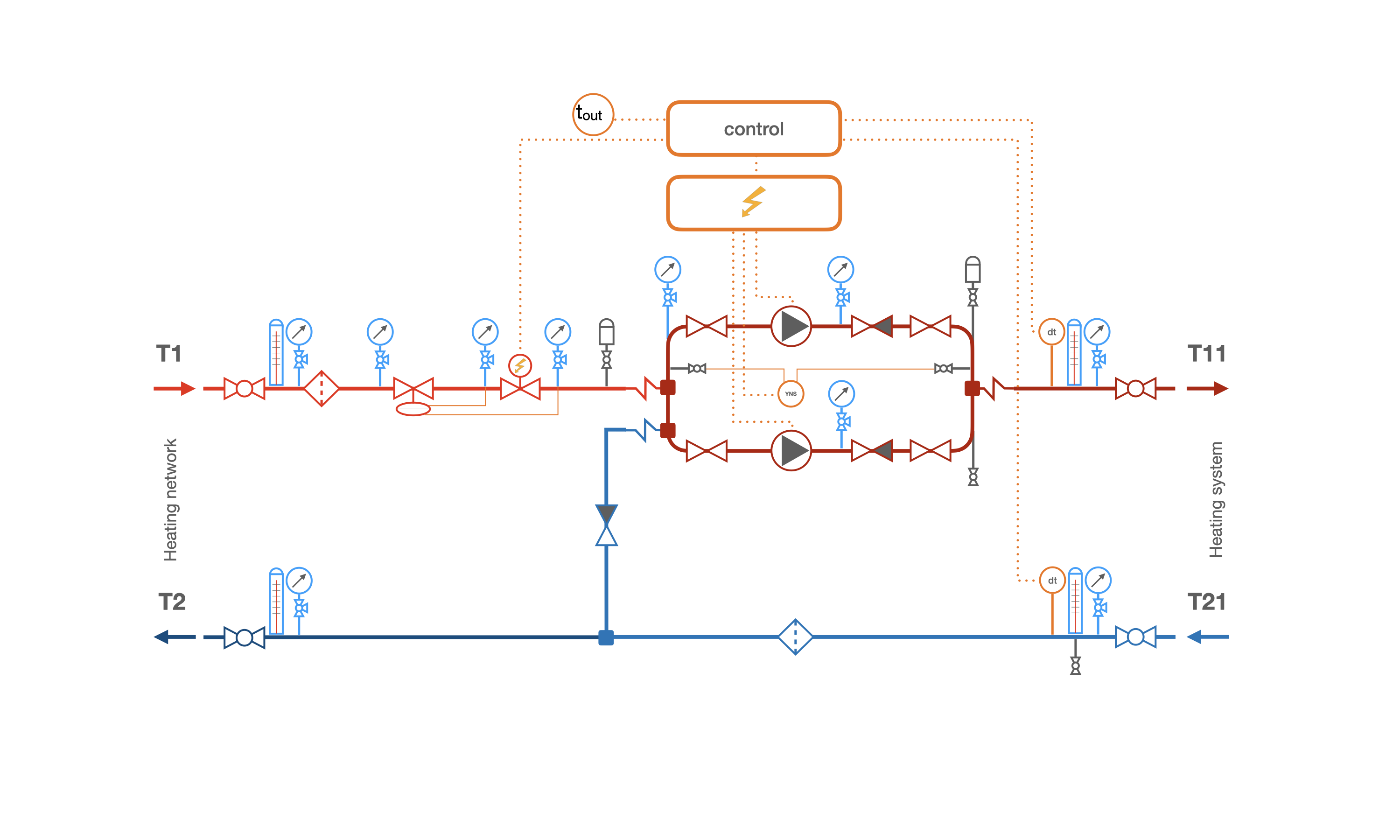

Operation of a district heating substation connected in a dependent scheme

The operation of a district heating substation is controlled by a programmable controller connected to the electric drive of the valve, which affects the selection of the heat carrier from the district heating network, an outdoor air temperature sensor, and a heat carrier temperature sensor entering the heating system.

The controller inputs the dependence of the heat carrier temperature entering the heating system on the outdoor air temperature, day of the week, and time of day. The controller measures the outdoor air temperature periodically and compares the actual heat carrier temperature with the set temperature for the current conditions. If the temperature is lower than the set temperature, a signal is sent to open the regulating valve, and if it is higher, a signal is sent to close it.

A mixture of two heat carrier flows enters the supply pipeline of the heating system. One flow is 'hot' and comes from the district heating supply pipeline, passing through the regulator, while the other flow is 'cooled' and is mixed through a jumper from the return pipeline.

Regardless of whether the regulating valve is open or closed, there is a constant flow rate of the heat carrier circulating in the system, and the proportion of 'hot' and 'cold' flows in this volume depends only on the degree of closure of the valve at the inlet. That is, if the selection from the district heating network is completely closed, only water taken from the return pipeline through the jumper will enter the system.

Two silent wet rotor pumps create stable circulation in the heating system and mixing. One of the pumps always works, and the other is a spare in case of a breakdown of the working pump.

Advantages of a dependent connection of a district heating substation

1 Lower cost compared to an independent connection.

2 Possibility of automatic program control of the heating system operation mode.

3 The pressure in the heating system is stable and equal to the pressure in the return pipe of the heat source.

4 Easy start-up and mode configuration.

5 Possibility of supplying the heat carrier to the system at a temperature equal to the temperature of the heat carrier in the supply pipeline of the heating network (only if a three-way valve is used).

Disadvantages of a dependent connection of a district heating substation

1 The heating system will empty in case of water discharge from the heating network.

2 The circulation of water in the heating system will stop if the pumps are disconnected.

Types of dependent connection schemes of a district heating substation and when they are used.

How a Heat Substation with an Elevator Mixing Node Works

Elevator mixing nodes are installed in heat substations of buildings connected to a district heating network that operates in a quality control mode with 'superheated' water.

Quality control involves changing the temperature of the water supplied to the heating system depending on the outside air temperature while maintaining a constant flow rate of the circulating heat transfer fluid.

Water is considered superheated if it is supplied from the district heating network at a temperature higher than what is required for heating the building.

For example, the district heating network may operate on a schedule of 150/70, 130/70, or 110/70, while the heating system is designed for a schedule of 95/70. The 150/70 temperature schedule specifies that at the calculated outside air temperature (for Kiev, this is -22°C), the temperature at the district heating network inlet to the building should be 150°C, and the outlet to the district heating network should be at 70°C. Meanwhile, in the heating system designed for the 95/70 mode, this water should enter at a temperature of 95°C.

The elevator heat substation mixes the flow of water from the district heating network supply pipeline at 150°C with the flow of water exiting the heating system at 70°C. As a result of the mixing at the elevator output, a flow with a temperature of 95°C is obtained, which is supplied to the heating system.

How the Mixing Works

An elevator mixing unit is installed in the heating substations of buildings connected to a heating network operating in a quality control mode on 'overheated' water. Quality control involves changing the temperature of the water supplied to the heating system depending on the outdoor air temperature, with a constant flow rate of the circulating heat transfer fluid in it.

'Overheated' water is considered to be water that enters the heating network with a temperature that exceeds the required temperature for supplying the heating system. For example, the heating network can operate on a schedule of 150/70, 130/70, or 110/70, while the heating system is designed for a schedule of 95/70. The 150/70 temperature schedule assumes that at the calculated outdoor air temperature (for Kyiv, this is -22°C), the temperature at the input of the heating network to the building should be 150°C, and the output to the heating network should be 70°C. In this case, the water supplied to the heating system designed for the 95/70 schedule should have a temperature of 95°C.

The elevator heating unit mixes the water flow from the supply pipeline of the heating network with a temperature of 150°C and the water flow that came out of the heating system with a temperature of 70°C. As a result of the mixing, a flow with a temperature of 95°C is obtained at the output of the elevator, which is supplied to the heating system.

Advantages of Elevator Heating Units

1 Low-cost and simple.

2 Does not require maintenance.

3 Does not depend on the power supply.

Disadvantages of Elevator Mixing Units

1 Incompatible with automatic controllers, so their joint installation is strictly prohibited.

2 Creates a pressure difference on the input, and the heating system cannot exceed 0.15 bar. This prevents the installation of elevator heating units in buildings with heating systems equipped with thermostatic radiator valves.

3 The elevator unit has a constant mixing coefficient, which does not allow supplying the heating system with heat transfer fluid at the required temperature during underheating in the heating network.

4 It is too sensitive to pressure differences on the heating network's input. Reducing the pressure difference compared to the calculated value leads to a decrease in the volume flow rate of the circulating water in the heating system, which, in turn, leads to an imbalance in the system and the stoppage of its further branches.

5 The elevator requires a pressure difference of more than 1.5 bar between the supply and return pipelines to operate.

Where are heat substations with elevator nodes installed?

Practically all heating systems put into operation before 2000 are equipped with heat substations with elevator nodes.

Where can elevator substations be used?

Today, for all designed and reconstructed residential and administrative buildings, automatic control in the heat substation is mandatory. The use of elevator nodes together with automatic regulators is prohibited by regulations.

Elevator nodes can only be installed in objects where there is no need for automatic control of the heating system, the pressure difference between the supply and return at the input is stable and exceeds 1.5 bar, the pressure drop between the supply and return is sufficient for the connected heating system to operate at 0.15 bar, and the heating system operates with a constant flow rate of the heat carrier and is not equipped with automatic regulators.

question : comment : feedback

590

OTOS

Catalog of

Catalog of