Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Operating principle of the ball valve

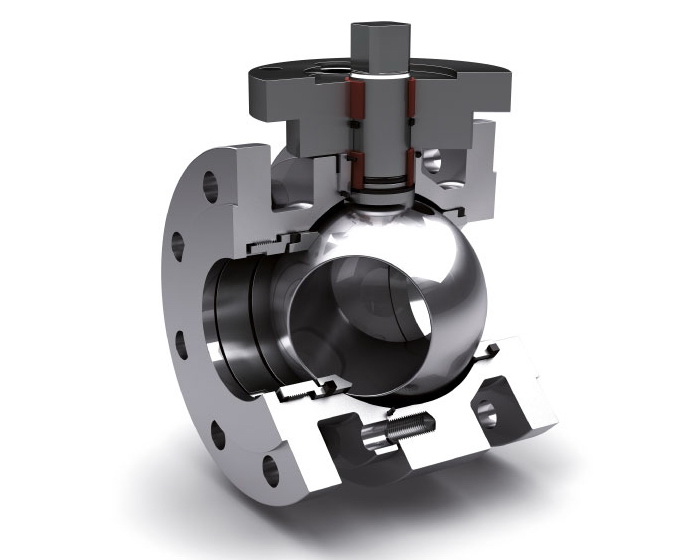

In the crane body, perpendicular to the pipeline axis, there is a ball valve made of polished stainless steel. The valve has a through hole with a diameter equal to or close to the diameter of the connected pipeline.

In the open position, the pipeline axis and the hole coincide, and when the ball is rotated by 90°, the hole axis moves into a plane perpendicular to the flow direction, covering the passage section with the ball wall.

The sealing between the polished surface of the ball and the body is provided by fluoroplastic end rings, which are pressed against the ball by tightening bolts or spring washers.

Ball valves are controlled by a lever, a reducer, a pneumatic or electric drive.

Lever (handle) control is used for valves with a nominal diameter less than DN125, and for larger diameters, due to the high forces required to close them, they install reducer drives.

Ball valves with electric drives are used for two-position regulation, remote control of fittings located in hard-to-reach and remote places, as well as for automation of the technological process.

A ball valve is a shut-off valve and is not designed for proportional control of the medium flow and should not be operated with partial ball rotation. Otherwise, the tightness of the flow closure will not be ensured due to the abrasive wear of the ball.

To open a ball valve, it is necessary to rotate the stem by 90°, which requires significant torque, so electric drives for ball valves are equipped with gear mechanisms with a large gear ratio, which significantly complicates the design and increases the cost of the drive.

question : comment : feedback

331

Catalog of

Catalog of of ball valves

IVR

IVR

IVR

Genebre

Genebre

Breeze

Breeze

Breeze

Breeze

Ayvaz

Danfoss

Brandoni

Brandoni

Vexve

Vexve

Vexve

Vexve

Vexve

Vexve

FAF

FAF

Bray

LD

LD

Polix

Polix

Polix

Ukspar

Broen

Broen

Danfoss

Brandoni

IVR

Naval

Naval

Polix

Polix

FAF

Маршал

Маршал

Маршал

Genebre

Krom Schroder

ISO 5211

ISO 5211