Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

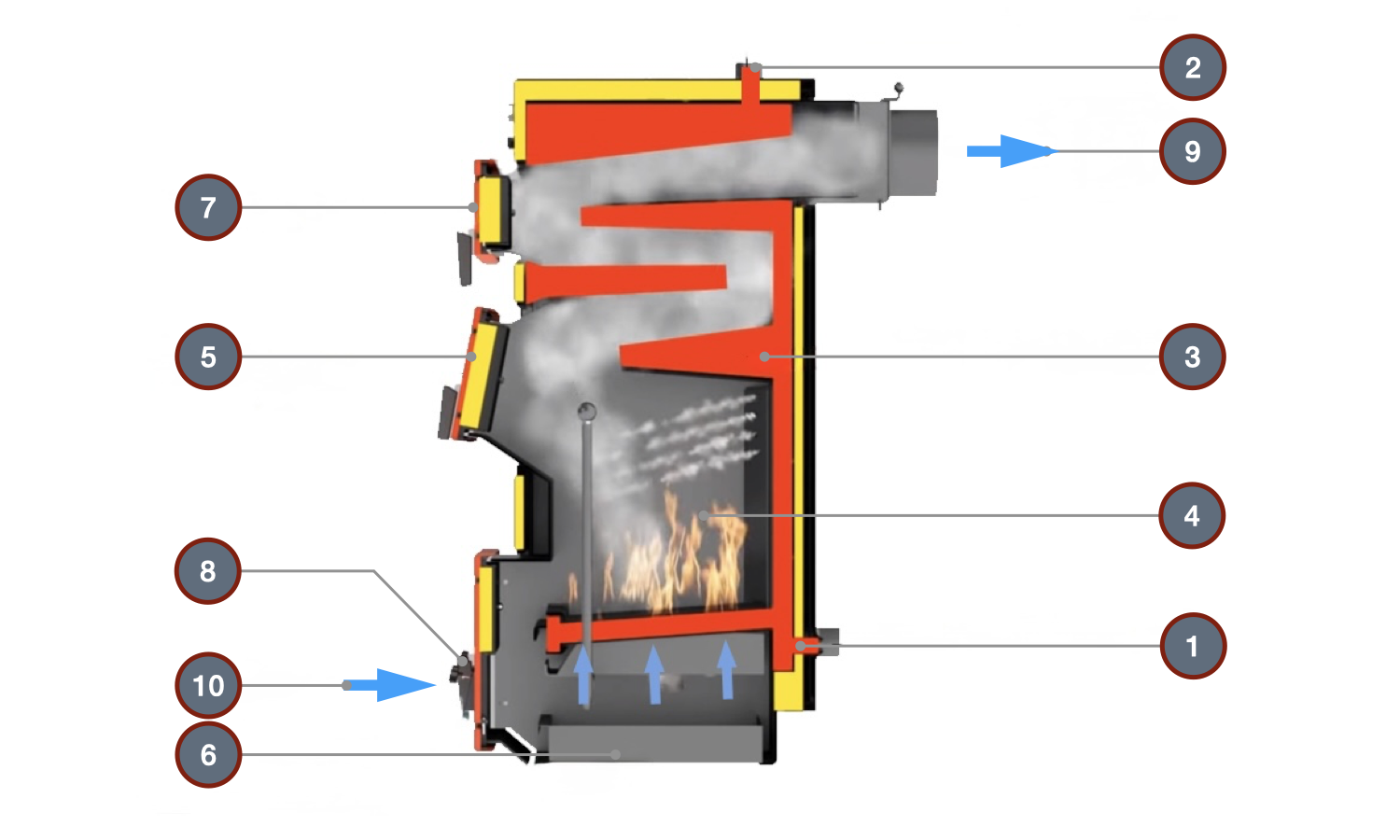

How the solid fuel boiler works

- 1 - Water inlet (heat carrier)

- 2 - Heated water outlet (heat carrier)

- 3 - Water circuit between the steel plates of the boiler

- 4 - Boiler furnace

- 5 - Fuel loading window

- 6 - Ash collection box

- 7 - Inspection window

- 8 - Air supply damper

- 9 - Flue gas outlet

- 10 - Combustion air inlet

Below is described the operating principle of a small-scale solid fuel boiler (up to 100 kW), boilers with higher power may have a different design.

The combustion chamber of a solid fuel boiler is surrounded on all sides by a hollow casing with water cooling.

Fuel loading into the combustion chamber and ignition are done through a loading door, which is then closed. Air necessary for combustion is supplied through an air damper in the ash door.

The heat generated during fuel combustion heats the steel wall of the combustion chamber and is transferred to the circulating water through the boiler. Cooling of combustion products outside the combustion chamber takes place in a labyrinth of heat exchange shelves on the path of the exhaust gases from the combustion chamber to the chimney.

To control the combustion process and maintain the desired water temperature at the outlet of the boiler, the air damper is closed, thereby changing the volume of air entering the combustion chamber. Water temperature control at the outlet of the boiler can be done manually by changing the position of the air damper or automatically using a thermostat regulator of draft.

Ash from burnt fuel through the slots in the grate falls into an ash pan, which must be periodically cleaned during operation. The frequency of cleaning the ash pan depends on the ash content of the fuel.

The outlet pipe of the heated water from the boiler is located at the top of the boiler, and the inlet pipe is at the bottom.

To regulate the draft on the exhaust pipe, a regulating damper with manual control using a lever is installed.

question : comment : feedback

518

Tutorial Viessmann

Tutorial Viessmann Catalog of

Catalog of