Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

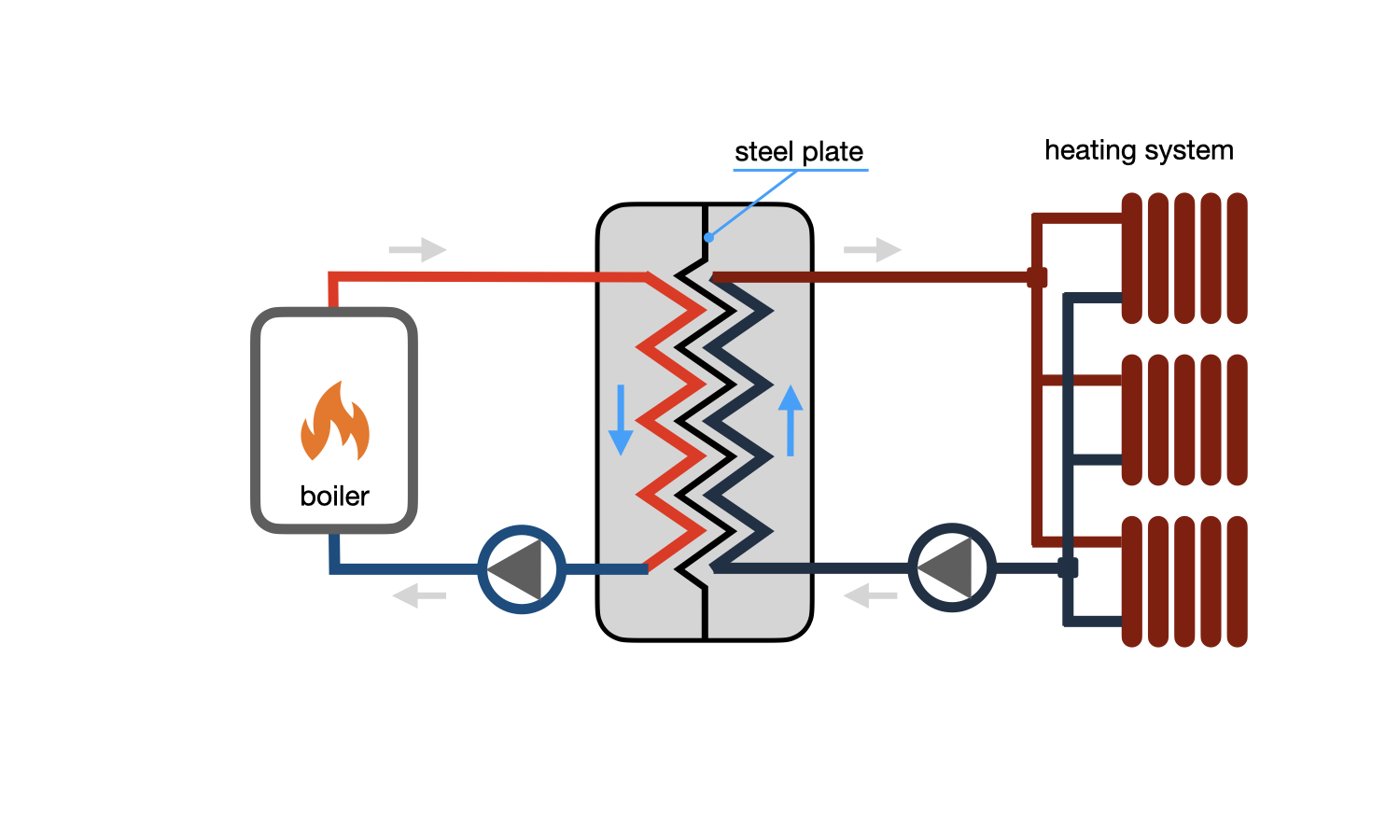

How a plate heat exchanger works

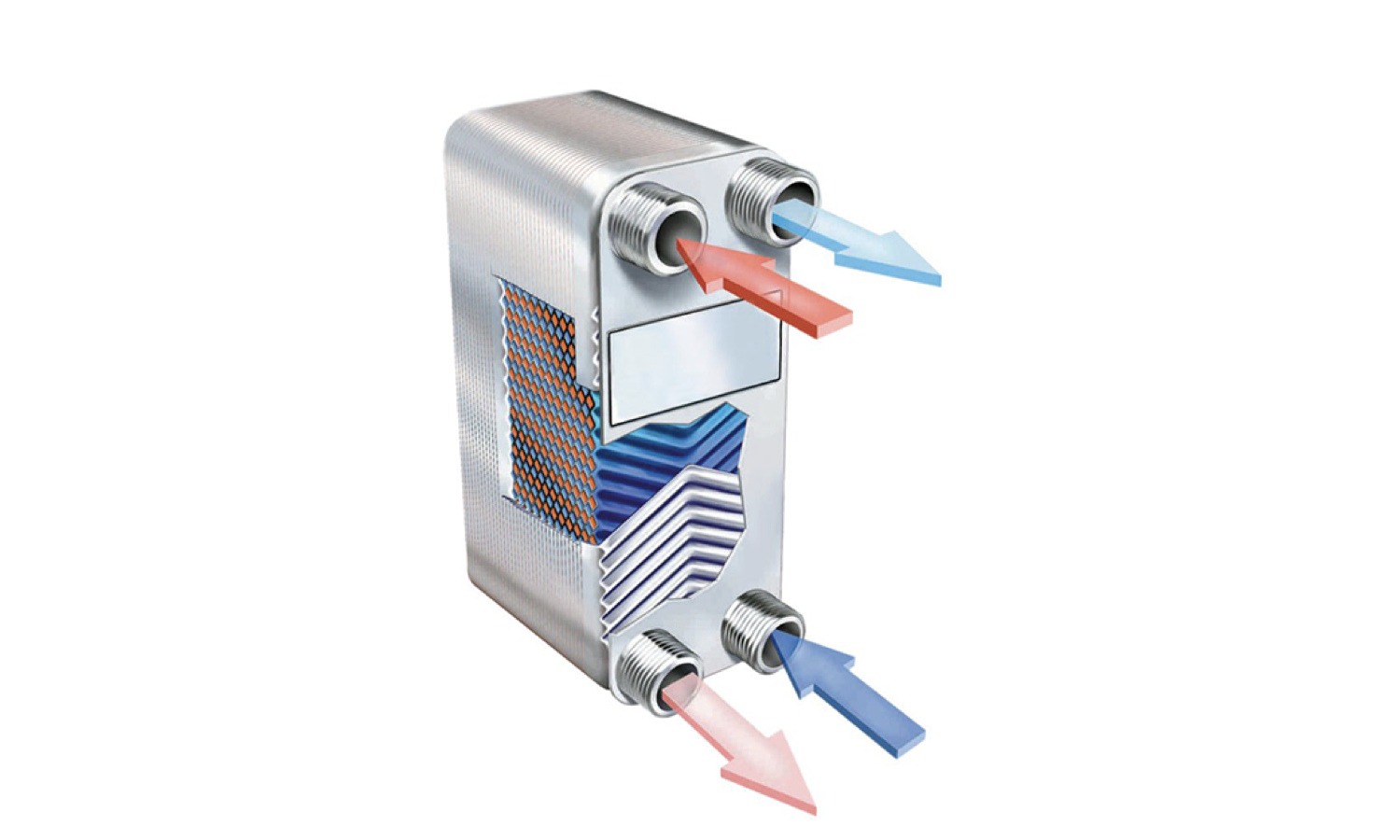

The working principle of a plate heat exchanger is based on transferring energy from a heating medium to a heated one through a stack of corrugated plates made of stainless steel. During the heat exchange process, the media do not mix with each other, interacting through the plates with a thickness of 0.4 to 1 mm.

The flow scheme of the heat carriers is organized in such a way that the heating water and the heated water move in different directions on one plate. Hot channels alternate with cold ones across the plate.

The heat exchanger block is assembled from corrugated steel plates with the same relief tightly pressed against each other. A polymer seal is placed at the points of possible mixing of flows, as well as around the perimeter of the plates. Each subsequent plate is rotated 180° relative to the previous one before installation in the block, forming a row of channels for water flow with bent corrugations. Hot and cold flows alternate in the block, collecting in collectors formed by holes in the upper and lower parts of the plates.

High intensity of the heat transfer process is achieved due to the countercurrent movement of the heating and heated water, as well as the corrugated surface of the plates forming a spiral turbulent flow. In addition to increasing the thermal performance, the plate relief promotes self-cleaning of stagnant zones and reducing scale deposits on the heat exchange surface.

The main characteristic of a plate heat exchanger reflecting the degree of its thermodynamic perfection is the heat transfer coefficient, which is equal to the number of watts transferred through one square meter of the plate area. The best performance of the heat transfer coefficient is achieved by improving the plate relief.

question : comment : feedback

395

Catalog of

Catalog of plate heat exchangers

Tranter

Alfa Laval

Funke

Sondex

Тепло-Поліс

Анкор-Теплоенерго

SWEP

Термопром