Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

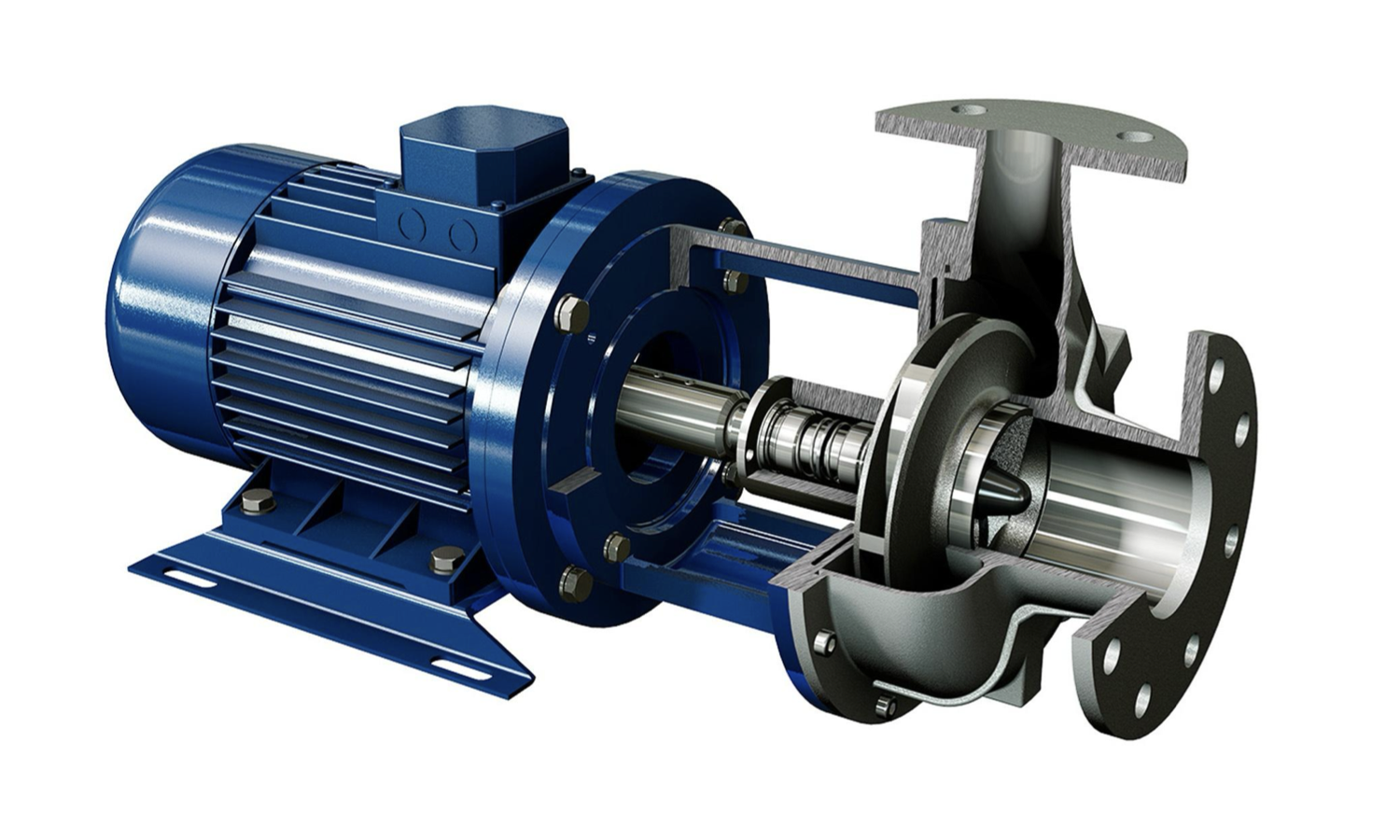

Service and Repair of Centrifugal Pump

Modern centrifugal pumps are quite reliable, and with adherence to the manufacturer's recommendations regarding installation and operation, they require repair extremely rarely.

Below is a general list of recommendations for the operation and maintenance of centrifugal pumps with air-cooled motor:

- It is not allowed to operate the pump without liquid, as running the pump 'dry' will lead to wear of the shaft seals. The wear of the sliding end face seal of the shaft is the most common cause of failure of monoblock pumps.

- The centrifugal pump should operate in the passport mode - the operating point on the head-flow characteristic should be within permissible limits. The pump should not operate with too high or too low flow rate. It is recommended that the operating point be located in the zone of maximum pump efficiency.

- During long periods of downtime, it is recommended to start the pump for short periods of time (5-10 minutes), at least once a month. Otherwise, oxidation of the shaft may occur, which may require pump repair.

- Freezing of water in the pump is not allowed, so the installation of pumps in premises with periodic temperature drops below zero is not recommended.

- In centrifugal pumps with mechanical shaft seals, the seal should be cool and should not allow too much fluid to pass through.

Possible malfunctions and methods of their elimination

| Malfunction | Cause | Repair |

|---|---|---|

| The pump turns on, makes noise, but the shaft does not rotate | The pump is blocked. The shaft oxidized after a long break in operation | In low-power pumps, the shaft can be unlocked by turning it with a screwdriver, for which a special notch is provided on the end face of the shaft. In high-power pumps, try to turn the shaft by grabbing its visible part or the impeller, after removing the cover of the housing. If the pump is blocked, do not leave the motor under power to avoid damaging the winding. |

| - - - | The pump is blocked. Foreign object has entered the impeller | Remove the pump housing cover and remove the foreign object. To prevent recurrence, install a mesh filter before the pump. |

| Power supply issues | Check if the power supply voltage corresponds to the pump's passport data, check the correctness of connections in the terminal box, and the presence of all phases. | Check and correct as needed. |

| The pump does not turn on or produce any sound | The power supply voltage is absent or does not correspond to the passport data. | Check and correct as needed. |

| - - - | The fuse has melted (if the pump is equipped with it) | Replace the faulty fuse. If the fuse replacement does not solve the problem, the motor winding may have burned out. |

| The pump produces sharp noise | Air has accumulated in the flow part | Release the air, and to exclude recurrence, install an automatic air vent at the top of the unit. |

| - - - | Cavitation in the pump (accompanied by vibration) | Increase the pressure in the pipeline at the pump inlet to a level that exceeds the cavitation margin. |

| - - - | The liquid level is below the suction level | This is typical for centrifugal pumps that lift water from a reservoir located below the axis of the impeller. Raise the water level or lower the pump. |

| Vibration of the pump | Worn bearing (accompanied by noise) | The worn bearing needs to be replaced. |

| - - - | Pump is not fixed properly | Fix it according to the manufacturer's installation instructions. |

| Pump does not provide passport flow and head values | Reverse rotation of the impeller | Typical for pumps with three-phase connection to the power grid, where the connection to the grid is incorrect. |

| - - - | Circulation ring has too much hydraulic resistance | Clean the filter, check the diameter of the regulating valves and pipelines according to calculation. |

| External motor protection activates immediately after startup | Problems with electrical system | 1. Check for all phases in the terminal box. 2. Check for open or dirty contacts of the circuit breaker. 3. Check for phase resistance to ground. |

| Motor protection activates too often | High temperature in the room | The temperature in the room should not exceed 40°C. Otherwise, the engine cooling is ineffective. |

| - - - | Bearings are malfunctioning | Check and replace if necessary. |

Attention! All maintenance and repair work on the centrifugal pump must be performed after disconnecting the power and draining the area.

question : comment : feedback

539

Tutorial Grundfos

Tutorial Grundfos Catalog of

Catalog of