Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Maintenance and repair of gate valves

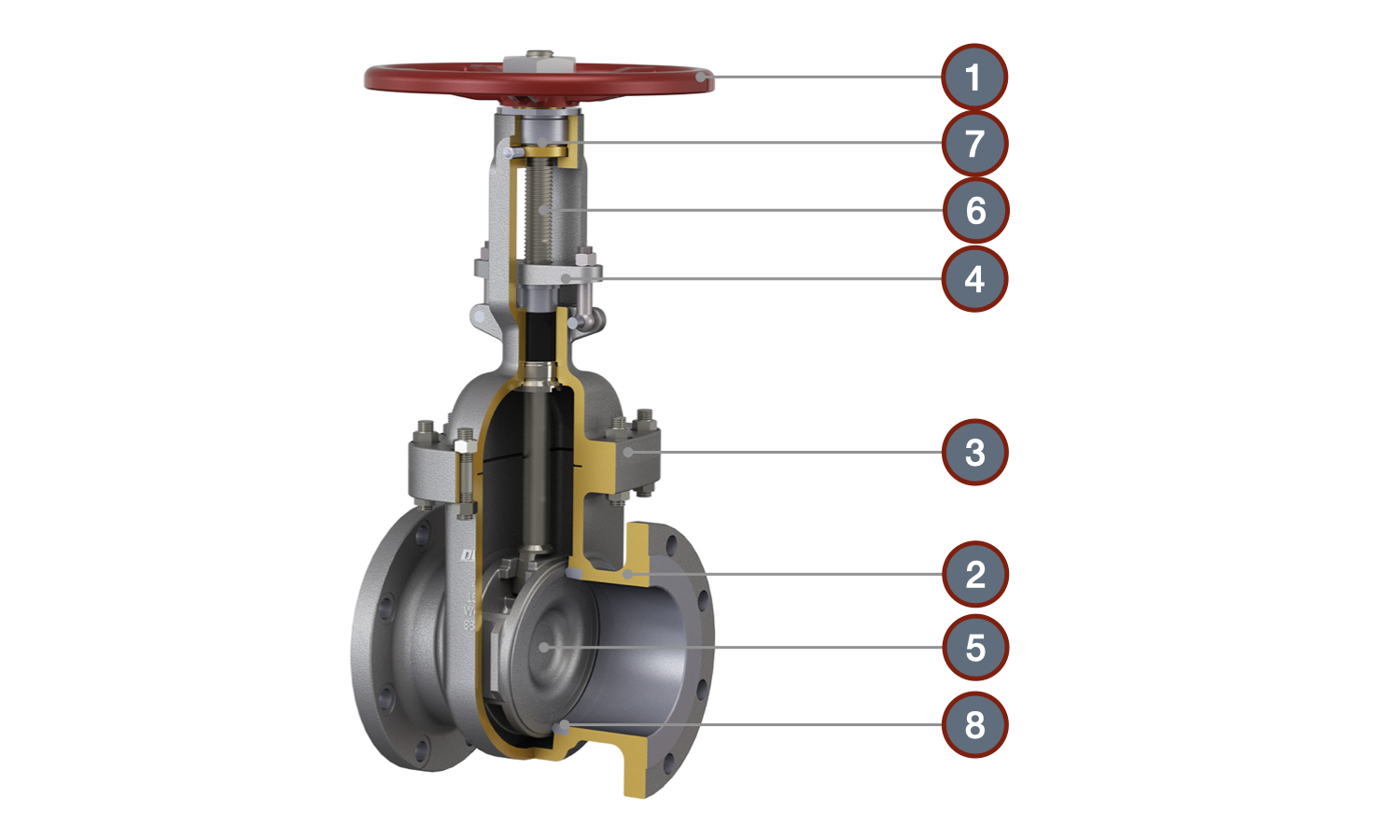

- 1 - Handwheel

- 2 - Body

- 3 - Body cover

- 4 - Stem packing gland cover

- 5 - Wedge gate

- 6 - Threaded stem

- 7 - Traveling nut

- 8 - Sealing rings

Possible malfunctions and their elimination methods

| Malfunction | Cause | Elimination |

|---|---|---|

| Non-sealing flow shut-off | Defects on the contact surfaces of the gate disk and the body (scaling, deposits, scratches) | Grind the sealing surfaces on the gate disk and the body. Usually, the contacting surfaces are made of bronze. To do this, remove the cover, pull out the gate disk, and if necessary, the body. Grinding is carried out with diamond pastes of different grits with a gradual transition from coarse to fine. It should be noted that in wedge gate valves, after several grindings, the gate wedge may collapse, which leads to a loss of tightness even with ground surfaces of the wedge. |

| Leakage under the gland along the stem | Loose stem packing | Tighten the gland, and if necessary, replace the packing. If the leakage was not eliminated after replacing the packing, it is likely that corrosive deposits have formed in the stem and it will need to be welded or replaced. |

| The handwheel cannot be turned | The gate is stuck | This problem occurs in gate valves that are not used frequently and are out of the service personnel's attention. The reason is deposits on the sealing surfaces. To solve this problem, it is necessary to remove the upper cover of the gate valve and clean the sealing surfaces of the disk and the body. If necessary, polish the friction surfaces. It is not allowed to hit the stem, as this may lead to the rupture of the guiding nut. |

| The handwheel turns, but the gate does not open | The gate valve is broken, the cheeks have collapsed | In gate valves with a rising stem, this problem occurs when the lugs of the stem that hold the gate valve are worn out or if the thread on the nut of the guiding stem is torn. If the problem is in the stem, it must be replaced or the worn lug must be welded. If the guiding nut is worn out, it should be replaced if the gate valve design allows it. In gate valves with a non-rising stem, the gate may fall out if the nut that is fixed in it is worn out. To eliminate the malfunction, it is necessary to replace the gate, as it is unlikely that the nut with a broken thread can be replaced. |

It is forbidden to disassemble a gate valve that is under pressure.

After installation, it is necessary to remove air from the valve. To do this, the bolts of the packing gland are loosened, and after water droplets appear from under the gland, the bolts are tightened again.

Maintenance recommendations

Once a month, perform a full cycle of opening/closing to clean the rubbing surfaces from a thin layer of deposits or sludge.

The stem of wedge gate valves with a rising stem should be kept lubricated.

Once a week, check the tightness of the stem seal and, if necessary, tighten or replace it. The replacement of the packing gland on a pipeline under pressure is not allowed.

The valve should not be in an intermediate position during operation. The valve is allowed to be either fully open or fully closed.

question : comment : feedback

394

Catalog of

Catalog of gate valves

ГОСТ

ГОСТ

Genebre

Genebre

IVR

CMO

CMO

CMO

CMO

Hawle

Hawle

Hawle

Ukspar

Ukspar

Brandoni

Brandoni

AEON

FAF

AVK

AVK

AVK

Herz

Polix

Polix

Polix

IMI Hydronic

IMI Hydronic

Oventrop

Oventrop

FAF

Zenit

EBRO Armaturen

AVK

AVK

AVK

AVK