Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Installation schemes of auto bypass valves

A bypass valve is installed in the bypass line in the pump assembly for systems with highly variable flow rates. When the flow rate in the system, and therefore through the pump, decreases, the head generated by the pump increases, resulting in an increase in the differential pressure between the suction and discharge ports of the pump. The bypass valve responds to this increase and opens, allowing the heat transfer fluid to flow from the discharge port to the suction port, thereby maintaining a constant flow rate through the pump.

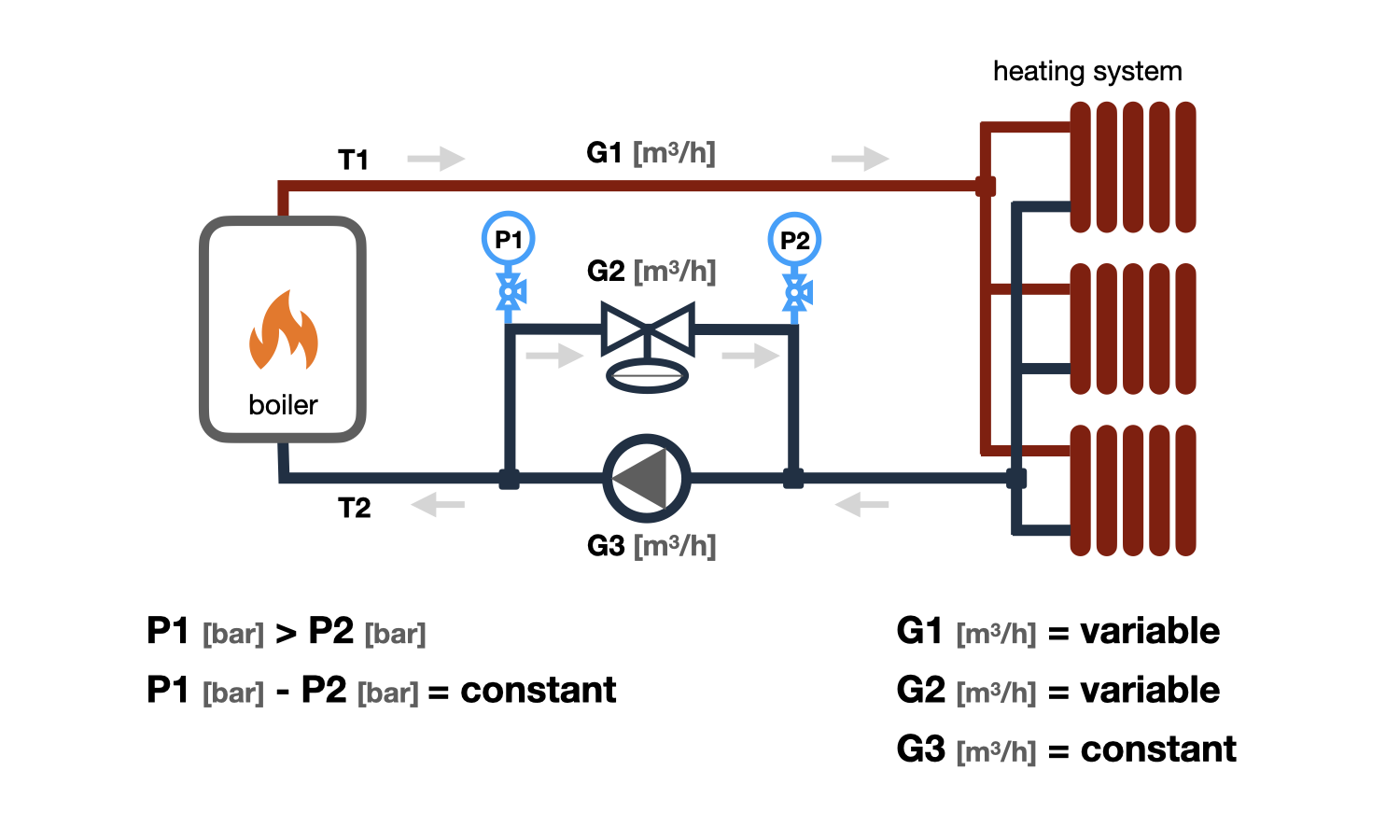

The bypass valve is installed in the jumper between the supply and return piping in the non-condensing boiler assembly. In this configuration, it is necessary for creating an optimal operating mode for boilers in heating systems with thermostatic radiator valves and heat flow regulators.

When the regulators close, the flow rate of the heat transfer fluid circulating in the system decreases, which increases the head generated by the pump and, consequently, the differential pressure between the supply and return piping in the boiler room. The bypass valve responds to the increase and, by opening, bypasses the hot heat transfer fluid from the supply piping to the return piping, thereby ensuring a stable flow rate through the boiler, independent of flow rate fluctuations in the system.

In addition, hot heat transfer fluid enters the boiler, which reduces the probability of condensation of exhaust gases on the heat exchange surface of the boiler.

The purpose of the bypass valve in each of the described configurations is to create an optimal operating mode, both for individual elements and for the heating system as a whole.

question : comment : feedback

851

Tutorial Herz

Tutorial Herz Catalog of

Catalog of