Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Installation of the check valve

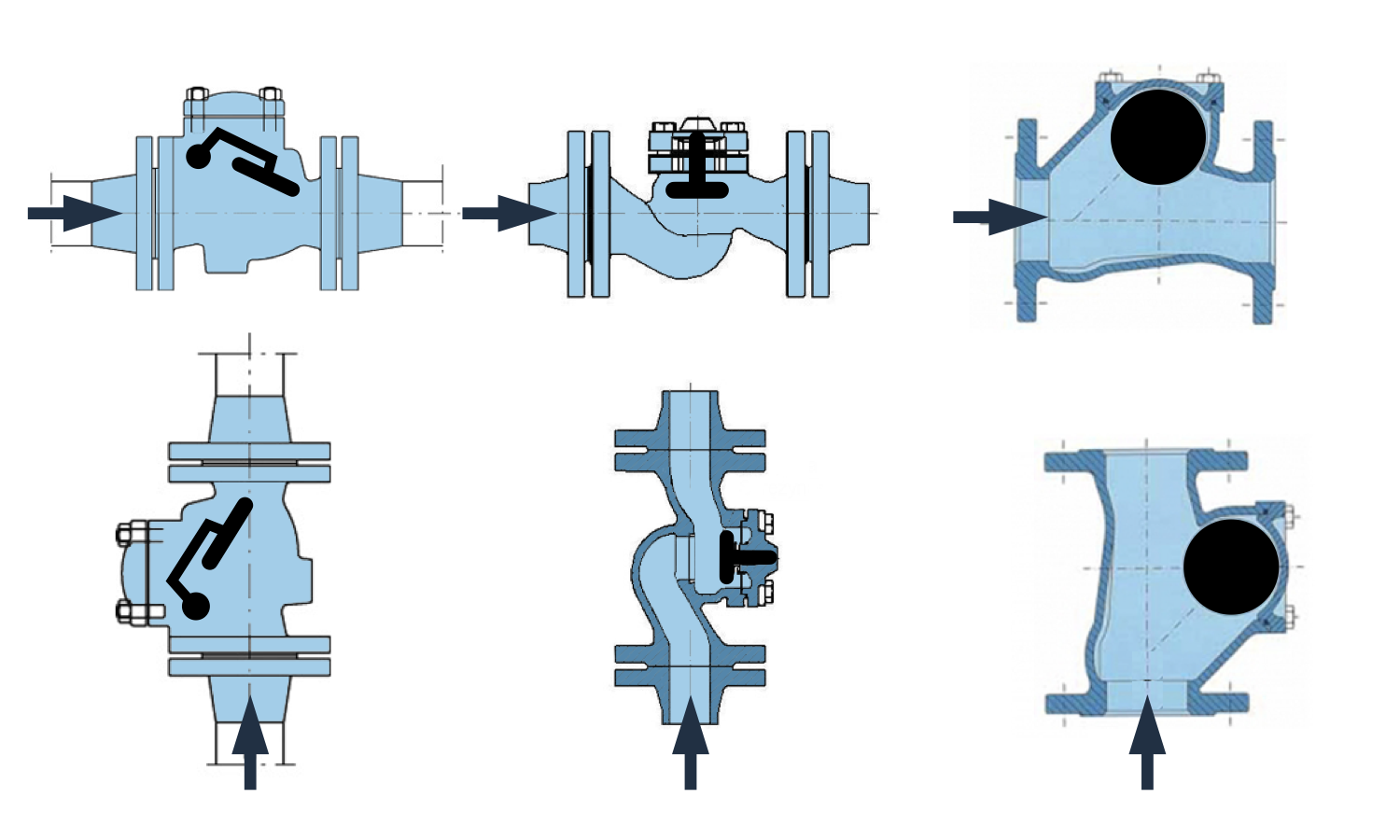

Spring-disc and lift check valves can be installed in any position with any flow direction.

Non-spring check valves should be installed on a horizontal pipeline or on a vertical one with the flow direction from bottom to top. When installing a ball check valve on a horizontal pipeline, the ball chamber must be above the pipeline axis.

Check valves, whose disc is held closed by a lever mechanism, may only be installed on a horizontal pipeline.

The body of the check valve must not be subjected to torsion, tension, bending, or compression from connected pipelines.

The corresponding flanges must be parallel. It is not allowed to correct flange misalignment by installing additional gaskets or uneven tightening of bolt connections.

When installing a check valve on long straight sections of the pipeline exposed to temperature fluctuations of the working medium or ambient air, a fixed support or axial compensator with guides should be installed to prevent pipeline displacement relative to its axis.

Before installing the check valve, remove the plugs that block the passage. In some valves, an additional insert is provided to hold the disc in place during transportation, which must be removed before installation.

Do not damage the paint coating of the valve body, as it serves not only a decorative purpose but also protects the check valve body from corrosion.

The arrow on the body must match the correct flow direction according to the process diagram.

The connecting bolts should be installed so that the nuts are located on the side of the check valve flange. The bolts should be tightened diagonally, in a cross pattern.

It is not allowed to lift the valve by the holes in the connecting flanges.

Installing a mesh filter before the check valve increases its service life.

question : comment : feedback

220

Catalog of

Catalog of сheck valves

Zetkama

Zetkama

Genebre

ГОСТ

Danfoss

CMO

CMO

CMO

Honeywell - Resideo

Ukspar

Hawle

Brandoni

Brandoni

Brandoni

IVR

ARI Armaturen

FAF

Oventrop

Polix

Polix

Polix

AVK

AVK

EN 1092-1

EN 1092-1