Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

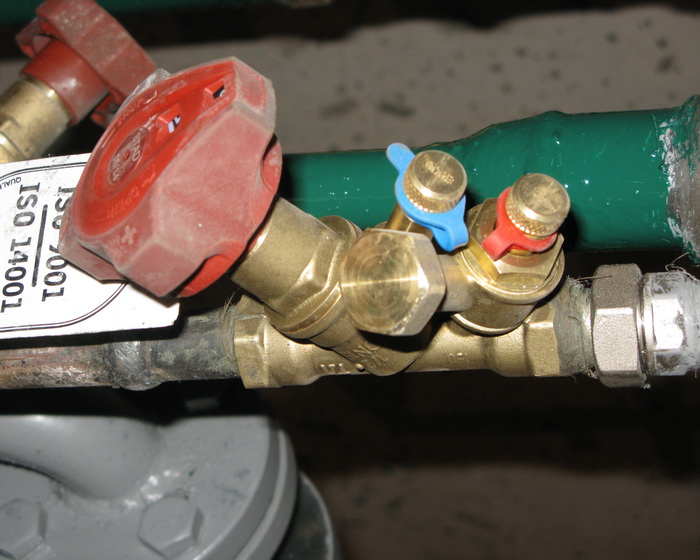

Installation of stop valve

- The shut-off valve can be installed in any position relative to the horizon, provided that there is free access for maintenance and repair.

- The direction of water flow at the valve location should correspond to the arrow on the body. Long-term operation with reverse flow direction may cause the valve to break.

- The connected pipelines should be aligned, and the valve body should not be subjected to twisting, stretching, bending, or compression from them.

- Supports are not allowed directly under the valve body.

- The edge of the pipe thread should not be pressed into the end of the valve thread.

- To seal the threaded connection, you can use flax, Teflon tape, sealant, or glue.

- Leakage through the threaded connection and valve stem is not allowed.

- Cast iron shut-off valves are not allowed to be installed on pipelines that are subject to vibration.

- Welding work is not allowed near the shut-off valve.

- After installation, hydraulic testing of the section should be carried out. The test pressure should not exceed the test pressure set for each of the tested elements. During hydraulic testing, shut-off valves, except for drain and check valves, should be in the fully open position.

Sequence for packing a threaded connection

1. Take a flax fiber string with enough threads so that its twisted diameter is approximately equal to the depth of the thread. The length of the string should provide for 1.5-2 times more windings than the number of thread turns.

2. Starting approximately 50-70 mm from the beginning of the string, slightly twist it, place it in the first thread turn, and, holding it with your hand, tightly wind a long branch of the string clockwise, placing it in each thread turn.

3. When reaching the end of the thread, continue winding with a second layer, shifting the turns to the beginning of the thread. The length of the second layer winding should be approximately equal to 2/3 of the thread length.

4. Wind the remaining end of the string (50-70 mm) similarly clockwise, from the end of the thread to its beginning.

5. Apply a layer of sealant to the winding surface.

6. Tighten the connecting elements by hand. With correct packing, the assembled element should turn 1.5-2 full rotations.

7. Continue tightening the element with a wrench or a torque wrench. In case the assembled element needs to be in a specific position, complete tightening it in the necessary position of the element.

With proper packing, during tightening, the force should not exceed the tightening torque listed below:

| DN15 | DN20 | DN25 | DN32 | DN40 | DN50 | DN65 | DN80 | DN100 |

|---|---|---|---|---|---|---|---|---|

| 70 Nm | 95 Nm | 120 Nm | 150 Nm | 190 Nm | 230 Nm | 280 Nm | 350 Nm | 400 Nm |

question : comment : feedback

287

Catalog of

Catalog of globe valves

Valtec RUS

ГОСТ

ГОСТ

ГОСТ

Herz

Herz

Herz

Danfoss

Danfoss

Honeywell - Resideo

ARI Armaturen

Oventrop

Danfoss

Zetkama

Oventrop

Oventrop

Oventrop

Honeywell - Resideo