Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Installation of the compact heat meter

Installation of a compact heat meter in some cities can take up to 3 months and is associated with obtaining a multitude of permits, developing a project, obtaining approvals from two authorities, installing the heat meter, and transferring it to commercial accounting.

Until recently, the installation of a heat meter in an apartment was unofficially prohibited and hindered by officials in heating supply organizations, although formally, it was the developers who were supposed to install heat meters in newly built apartments.

The reason why heating supply organizations did not want to register apartment heat meters lies not even in the fact that allegedly the apartment owner would pay significantly less for heating after the installation but rather in the complexity of processing data for each apartment and issuing bills based on its readings. In addition to the meter readings, the apartment owner must pay their share for heating common areas of the building and heat losses in transit pipelines. Moreover, all values must be recalculated monthly for each apartment based on the actual average monthly temperature outside.

It is impossible to install a heat meter for apartment heating yourself in the hope that it will be accepted by the heating supply organization. To install a heat meter, an individual project must be developed, which can only be done by a certified specialist. The installation of a compact heat meter can only be carried out by a licensed organization.

Requirements for installing a compact heat meter

- The installation of compact heat meters is carried out in accordance with the installation instructions and device metering unit project.

- The heat meter must be installed outside the apartment to allow representatives of the heating supply organization to access it. In some cases, with the consent of the heating supply organization, the installation of a heat meter inside the apartment is allowed.

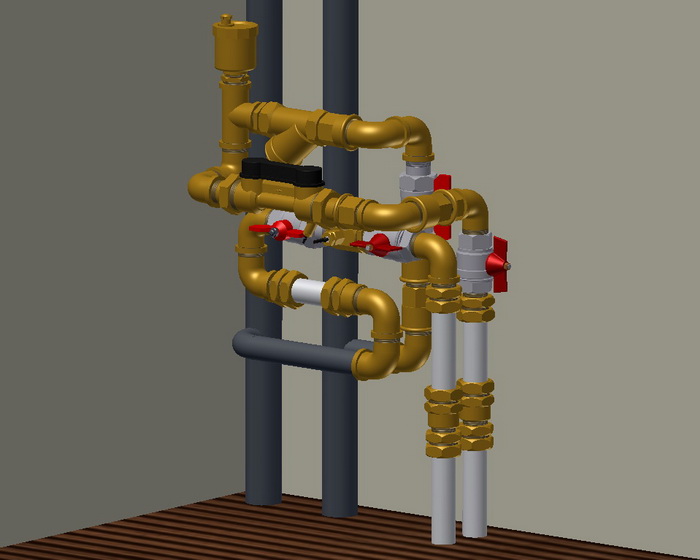

- Straight sections of pipelines must be provided before and after the flow meter to stabilize the flow of the heat transfer agent (stabilizing sections). For most models of heat meters, the stabilizing sections are built into the connecting fittings.

- The temperature sensor should be installed in such a way that the sensor's sensitive element protrudes to the axis of the pipeline.

- The installation must prevent the formation of air pockets in the flow meter section, regardless of whether it is an ultrasonic or mechanical device.

- To enable the disassembly of the flow meter for verification without draining the heating system, ball valves must be installed before and after it.

- A mesh filter must be installed before the heat meter in the direction of the heat transfer agent's flow.

question : comment : feedback

285

Catalog of

Catalog of compact heat meters

Zenner

Landis Gyr

Landis Gyr

Gross

Engelmann

Engelmann

DIEHL

Kamstrup

Apator

Sensus

Maddalena

Sontex

Sontex

Sontex

Itron

Itron

Landis Gyr

Kamstrup

Sontex

DIEHL

Sensus

Engelmann

Apator

Itron

Maddalena

EN 1092-1

EN 1092-1