Please do not block ads on our site. Clicks on ads help us exist, grow and become more useful for you!

Energy savings after the reconstruction of a District Heating Substation

First of all, it is important to understand that a reconstructed district heating substation is primarily the 'steering wheel' of the heating system, through which heat consumption can be reduced or increased, while increasing thermal comfort in the building to the desired level.

The savings achieved solely by avoiding overheating during warm days of the heating season for buildings located in Ukraine amount to approximately 15%.

Savings achieved by reducing the average temperature in heated rooms by 1°C during the entire heating season can further reduce heat consumption by 6%. Considering that after the reconstruction of the district heating substation, you will be able to control the temperature in the heated room yourself, you will have to decide whether to maintain an average temperature of 25°C or 20°C in the building, knowing that in the latter case you will have to pay 30% less for heating.

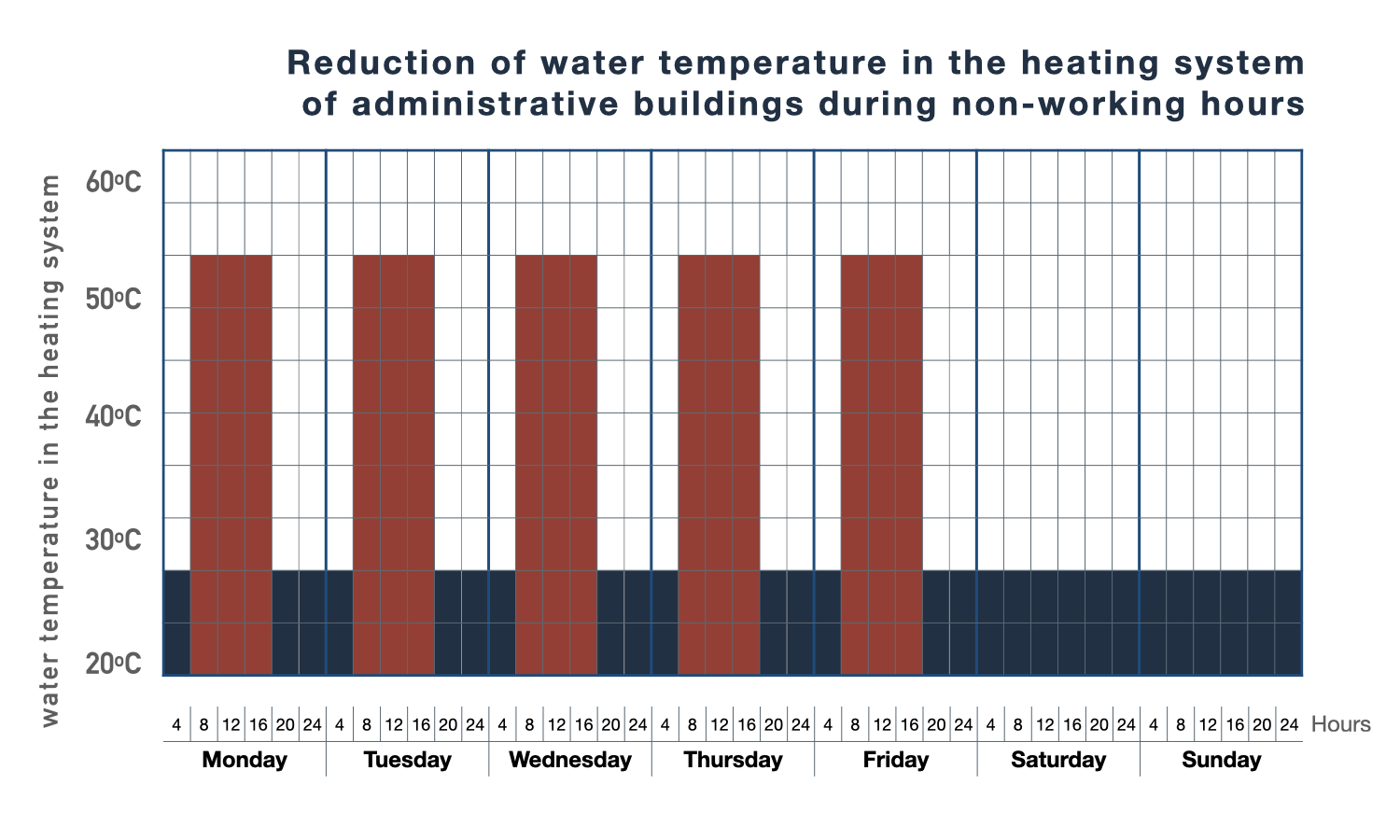

Additional savings can be achieved by lowering the temperature in buildings with a fixed working day during non-working hours, and in residential buildings - by slightly lowering the temperature at night.

Operation mode of the district heating substation before reconstruction

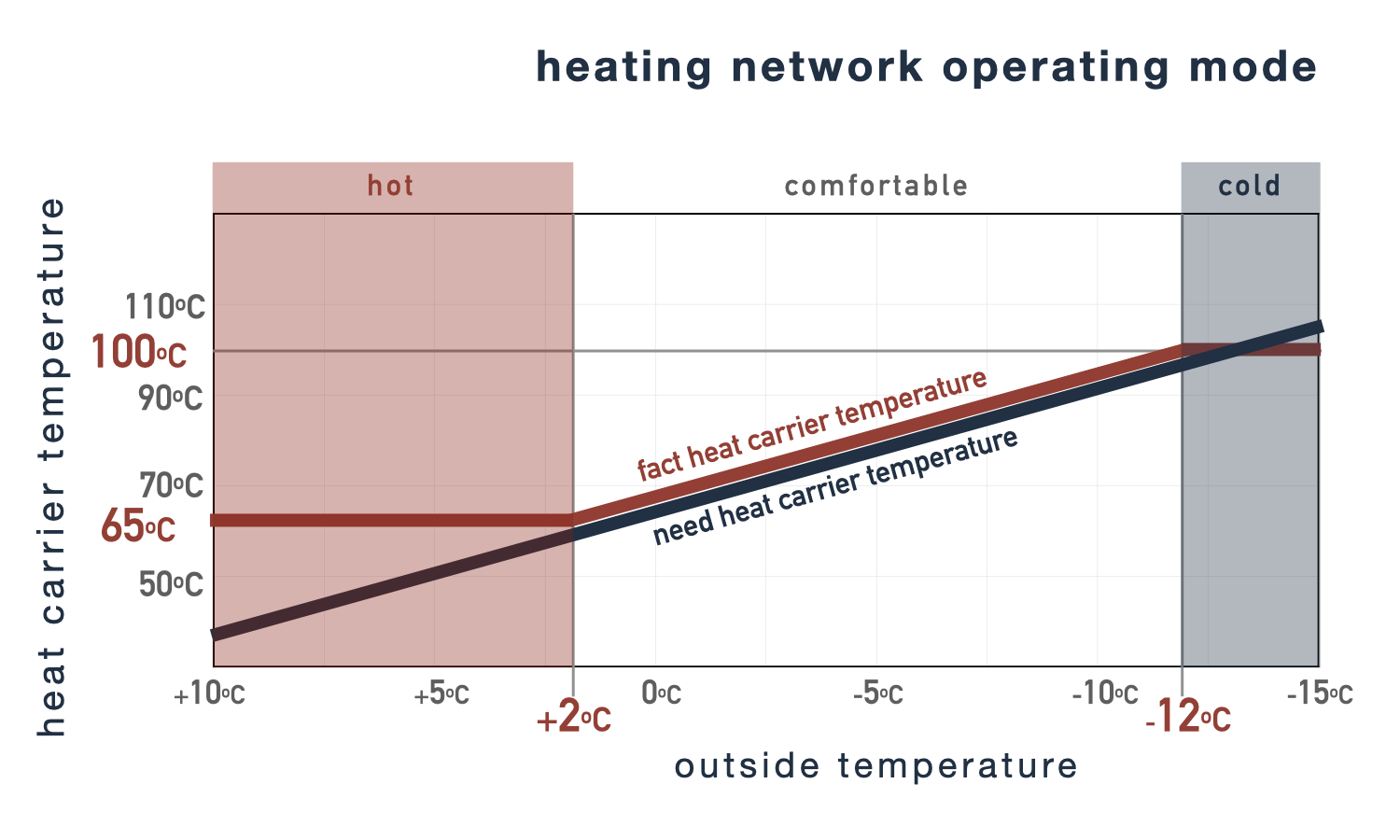

The district heating network supplies the heating medium to our buildings at a conditionally 'overheated' temperature regime depending on the weather.

WHAT DOES IT MEAN? It means that the temperature of the heating medium depends on the outside temperature, i.e., the colder it is outside, the hotter the heating medium will come. Conditionally overheated heating medium means that the temperature of the heating medium in the district heating network is always higher than the temperature required for the heating system.

In addition, there is a minimum supply temperature in the district heating network, below which the heating medium does not flow, even if according to the weather-dependent regime, it is necessary to supply a lower temperature. This is the so-called break point of the temperature graph, which is set at 65°C. According to the weather-dependent graph, 65°C corresponds to the outside temperature +2°C, which means that on all days with temperatures above +2°C, the district heating network supplies heating medium to our buildings at a higher temperature than necessary.

However, this does not happen because the district heating network overheats our buildings so that we pay more, but because at a lower temperature, they simply cannot supply the heating medium because they heat water for the hot water supply system, and to heat water for the HWS system to 55°C, it is necessary to heat it with hotter water.

The task of adapting the temperature regime at the district heating network inlet to the building is entrusted to the mixing elevator unit (also called a frame or a 'shoe'). The mixing elevator unit takes 1 m³ of water from the district heating network supply with a temperature of 70°C, mixes it with 2 m³ of water from the heating system return with a temperature of 40°C, and supplies the resulting 3 m³ of water at a temperature of 50°C to the heating system.

The mixing elevator unit is just a piece of iron. It does not know what the outside temperature is, what temperature the heating medium comes from the district heating network, and what temperature it supplies to the heating system. The only thing it does is take one cubic meter of water from the supply, mix it with two cubic meters of water from the return, and supply this mixture to the heating system.

Another problem with the mixing elevator unit is that it is not designed for regulation. Anyone who has tried to limit the intake from the district heating network by closing the valve in front of the mixing elevator unit knows that as soon as we reduce the flow rate of the heating medium, the flow rate of water circulating in the heating system immediately decreases, and as a result, the distant branches of the heating system stop working, and the uneven heating between the lower and upper floors intensifies.

As a result, we have:

1. Quality heat supply only when the heating network delivers the heat carrier precisely according to the temperature regime, and as soon as there is overheating on warm days or insufficient heating on cold days, we feel it in our apartments.

2. We cannot use the energy-saving potential hidden in automatic regulation.

What is done during the reconstruction of the district heating substation

1. Automation is installed in the district heating substation, which maintains the temperature of the water entering the heating system in accordance with the individually selected temperature schedule for your building.

2. A regulating valve with an electric actuator is installed on the supply pipeline of the heating network, which opens or closes the flow of the heat carrier according to the signal of the controller.

3. Two circulation-mixing pumps are installed to create a stable circulation of the heat carrier in the heating system, regardless of whether we are drawing the heat carrier from the supply, one of which is a backup.

The reconstructed heat substation works as follows:

The controller measures the outside temperature with temperature sensors, determines the temperature at which the heat transfer fluid should enter the heating system, and compares the calculated temperature with the actual one. If the heat transfer fluid entering the system has a lower temperature, the controller opens the valve on the heat supply and raises it to the required value. If the temperature exceeds the calculated value, the controller closes the valve.

What we get as a result of the heat substation reconstruction:

1. Stable circulation in the heating system regardless of whether we extract heat transfer fluid from the heating network or not.

2. The temperature of the heat transfer fluid is always adequate to the outside temperature.

3. The ability to control the heating system and use the energy-saving potential embedded in this regulation.

question : comment : feedback

185

OTOS

Catalog of

Catalog of