Veuillez ne pas bloquer les publicités sur notre site. Les clics sur les annonces nous aident à exister, à nous développer et à devenir plus utiles pour vous !

Installation du clapet anti-retour

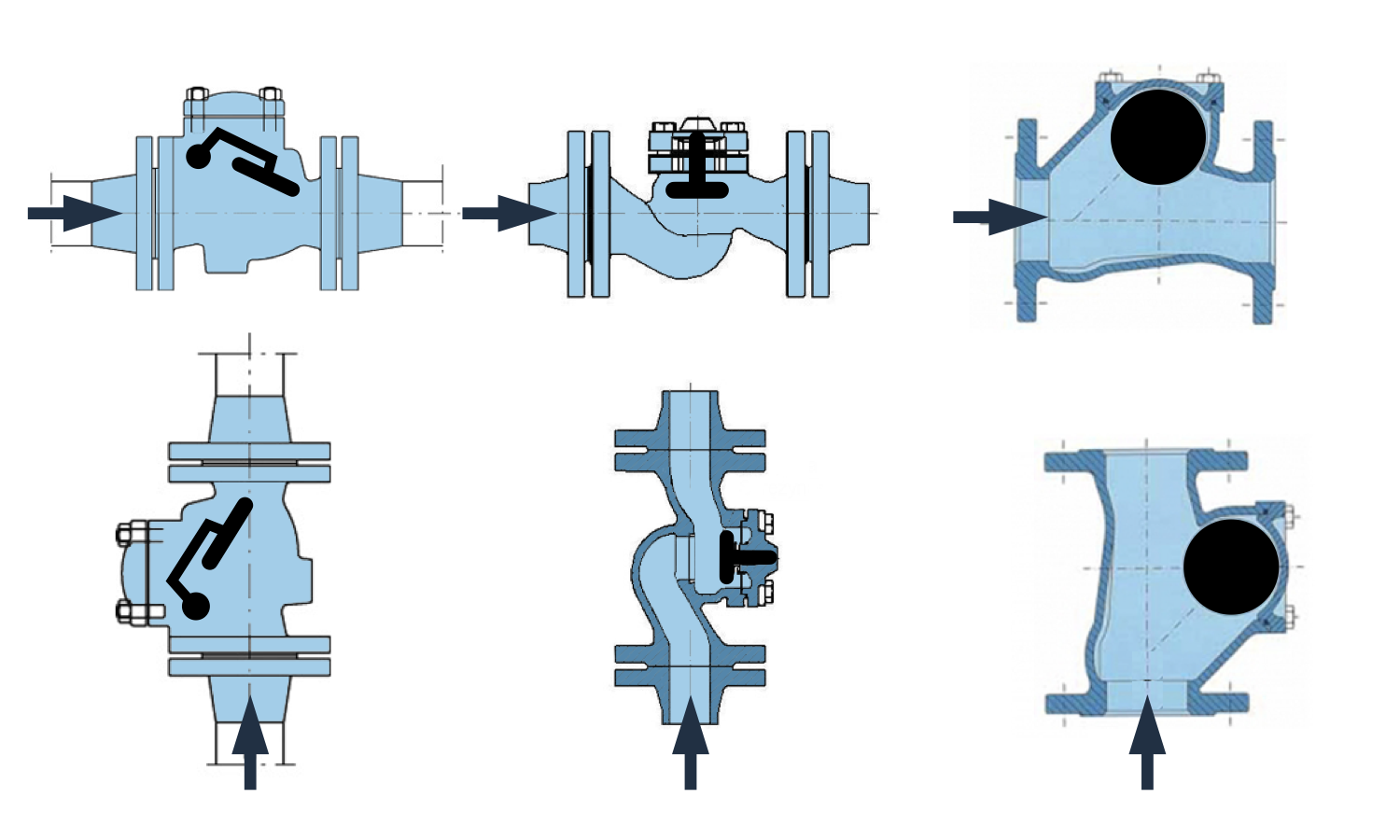

Les clapets anti-retour à ressort-disque et à levée peuvent être installés dans n'importe quelle position avec n'importe quelle direction d'écoulement.

Les clapets anti-retour sans ressort doivent être installés sur une conduite horizontale ou verticale avec un écoulement de bas en haut. Lors de l'installation d'un clapet anti-retour à bille sur une conduite horizontale, la chambre de la bille doit être située au-dessus de l'axe de la conduite.

Les clapets anti-retour dont le clapet est maintenu fermé par un mécanisme à levier ne peuvent être installés que sur une conduite horizontale.

Le corps du clapet anti-retour ne doit pas être soumis à des forces de torsion, de traction, de flexion ou de compression des conduites connectées.

Les brides correspondantes doivent être parallèles. Il n'est pas permis de corriger le désalignement des brides en installant des joints supplémentaires ou en serrant inégalement les connexions boulonnées.

Lors de l'installation d'un clapet anti-retour sur de longues sections droites de la conduite exposées à des fluctuations de température du fluide de travail ou de l'air ambiant, un support fixe ou un compensateur axial avec des guides doit être installé pour éviter tout déplacement de la conduite par rapport à son axe.

Avant d'installer le clapet anti-retour, retirez les bouchons qui bloquent le passage. Dans certains clapets, un insert supplémentaire est prévu pour maintenir le clapet en place pendant le transport, et il doit être retiré avant l'installation.

Ne pas endommager le revêtement de peinture du corps, car il ne sert pas seulement à des fins décoratives, mais protège également le corps du clapet anti-retour contre la corrosion.

La flèche sur le corps doit correspondre à la bonne direction d'écoulement selon le schéma de processus.

Les boulons de connexion doivent être installés de manière à ce que les écrous soient situés du côté de la bride du clapet anti-retour. Les boulons doivent être serrés en diagonale, en croix.

Il n'est pas permis de soulever la vanne par les trous dans les brides de raccordement.

L'installation d'un filtre à mailles avant le clapet anti-retour augmente sa durée de vie.

question : commentaire : retour

220

Catalogue de

Catalogue de clapets anti-retour

Zetkama

Zetkama

Genebre

ГОСТ

Danfoss

CMO

CMO

CMO

Honeywell - Resideo

Ukspar

Hawle

Brandoni

Brandoni

Brandoni

IVR

ARI Armaturen

FAF

Oventrop

Polix

Polix

Polix

AVK

AVK

EN 1092-1

EN 1092-1